TRIMINATOR T1000™

TRIMINATOR T1000™

"COME WITH ME IF YOU WANT TO SPRAY!"

Manufacturer: Total Finishing Solutions

Part #: L002583

Description: Automatic spray machine for profiles. The TRIMINATOR T1000™ machine is suitable for automatic painting of different types of profiles, transferring lengthwise inside the machine. The feeding direction is available either right to left or left to right

Configurations include:

- Automatic VIPER-X® - Air Assisted Airless Spray Guns

- Medusa™ 30:1 Pump - Includes Fluid Regulator & Manifold Filter

-

Anest Iwata 36:1 iCON Series Pump - Includes Fluid Regulator & Manifold Filter

- Pumps come with wall mounting brackets as standard, or can be mounted to a cart or stand.

|

Hulk Conveyor™ Infeed / Outfeed Conveyor |

|

Total Finishing Double Head Brush Sander Twin Top Head Sanding Unit |

Intro Video

Training Video

T1000 360° View

Features:

- Metal frame structure and tubular, welded and painted reinforcements.

- Support base, with feet for height adjustment.

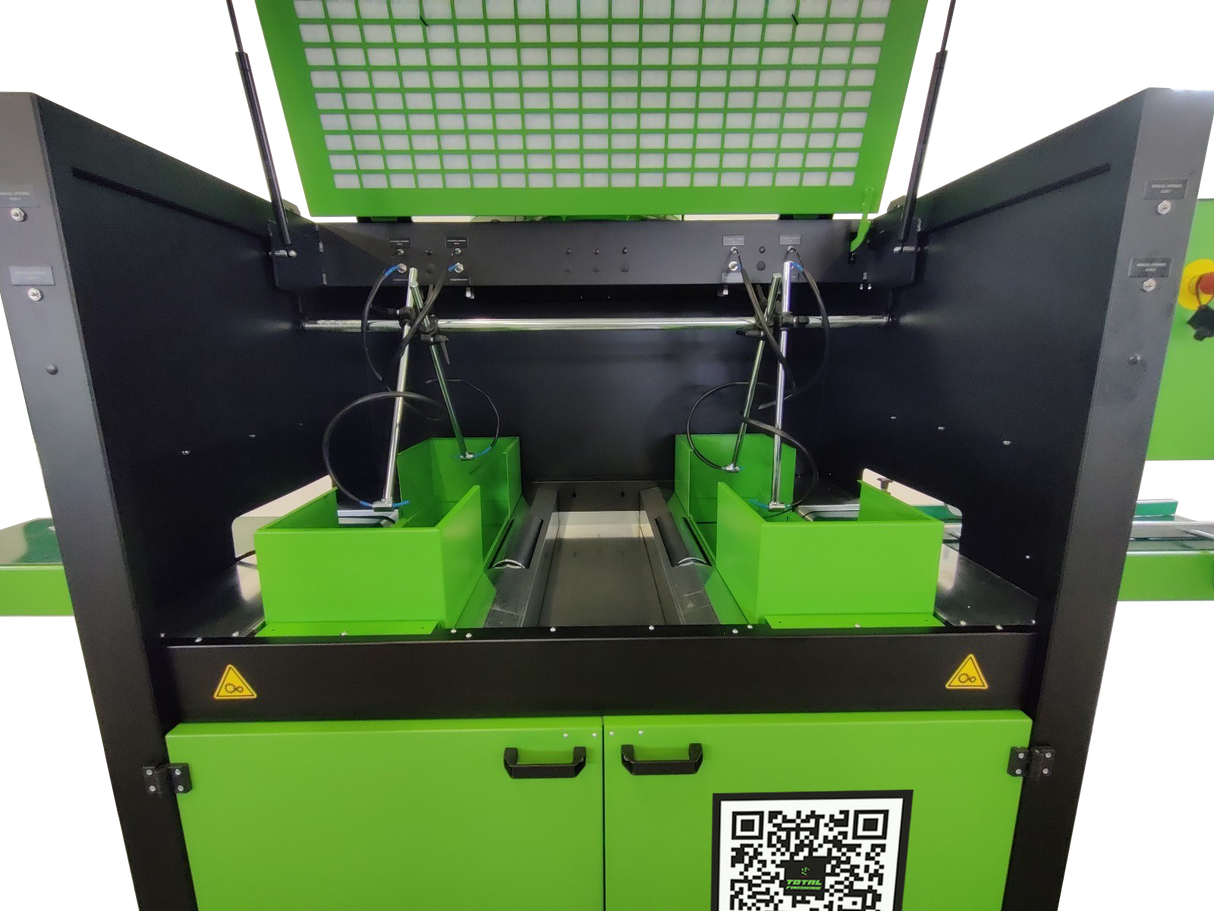

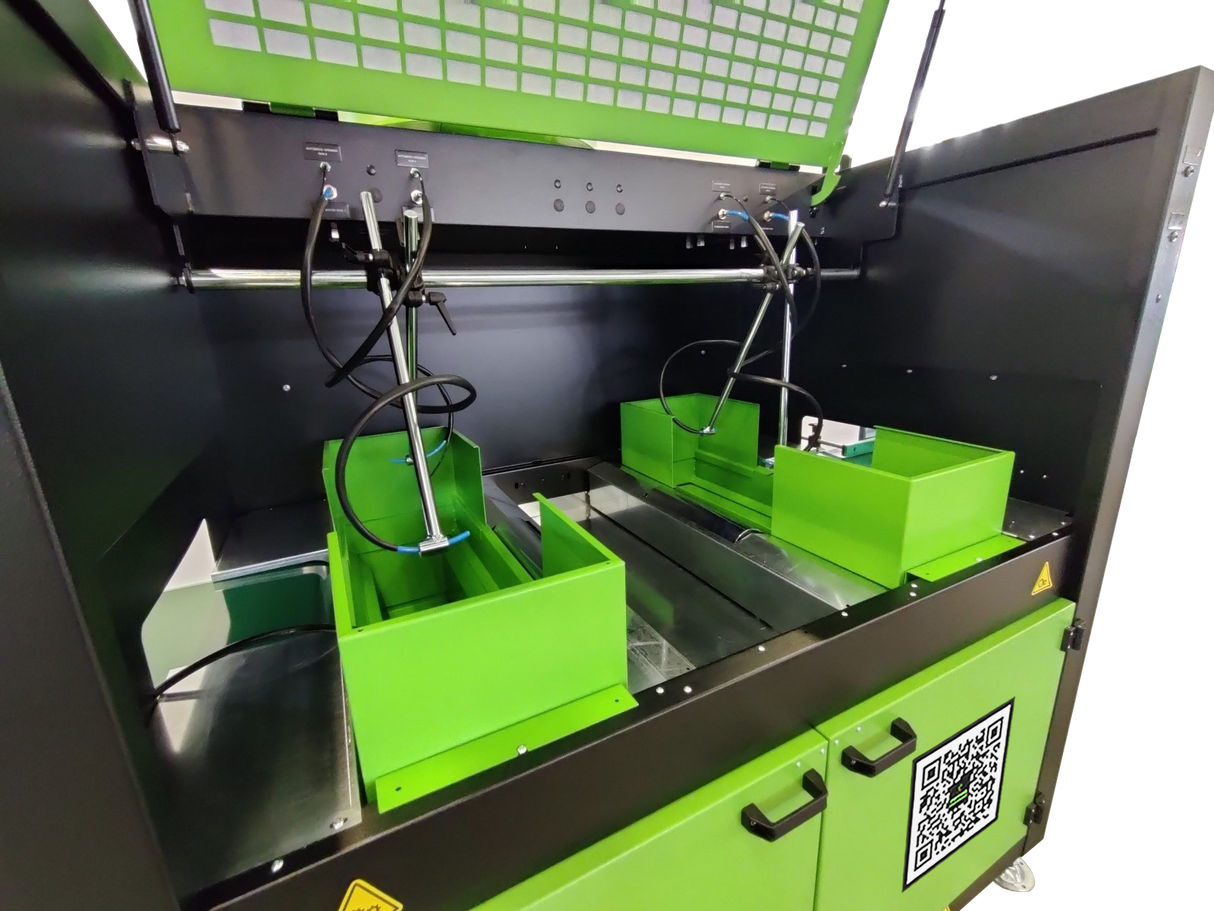

- Fixed suction trolley integrated in the machine equipped with a suction opening towards the rear suction tower, as well as with front removable panel. The suction trolley has got on the upper side, inside the cabin, 2 suction channels, 2 tanks for paint drain, and relative tank covers, all removable from inside the cabin.

- Structure of the in-feed and out-feed conveying elements, suitable for supporting the drives to the machine rollers. Motorized belt conveyors both at the infeed and at the out-feed of the machine, advancement by means of motorized rollers between the two spraying tanks.

- In-feed conveyor equipped with adjustable side guides and pressure wheel complete with microswitch.

- Motor drive of the conveying elements by means of gear-motors, controlled by inverter.

- Phonic wheel and reading sensor for spraying control.

- Rollers driven by means of a flat belt, placed on the front of the machine.

- Spraying booth equipped with an opening door with upper hinges, complete with gas springs, with front tempered glass on the door, all assembled with a special gasket; net booth ceiling, equipped with filtering sponge.

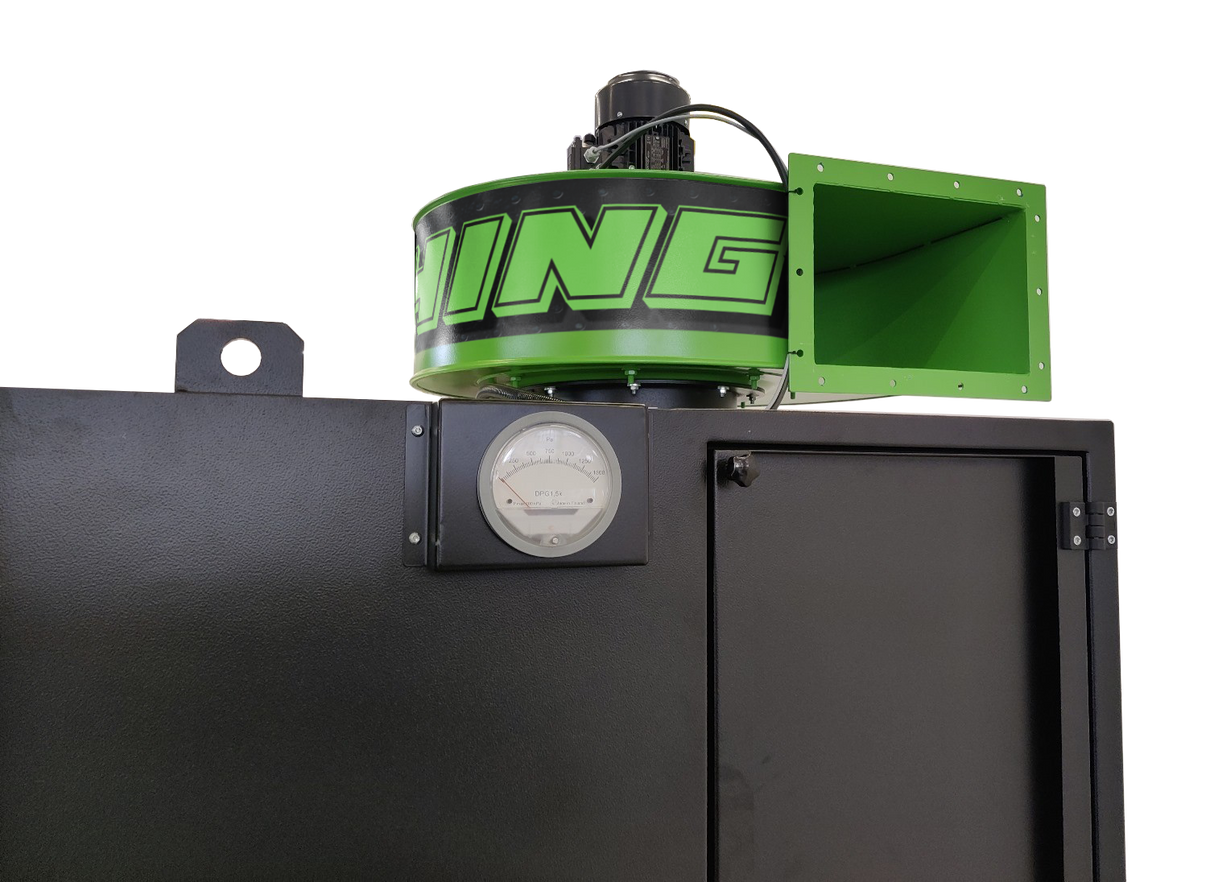

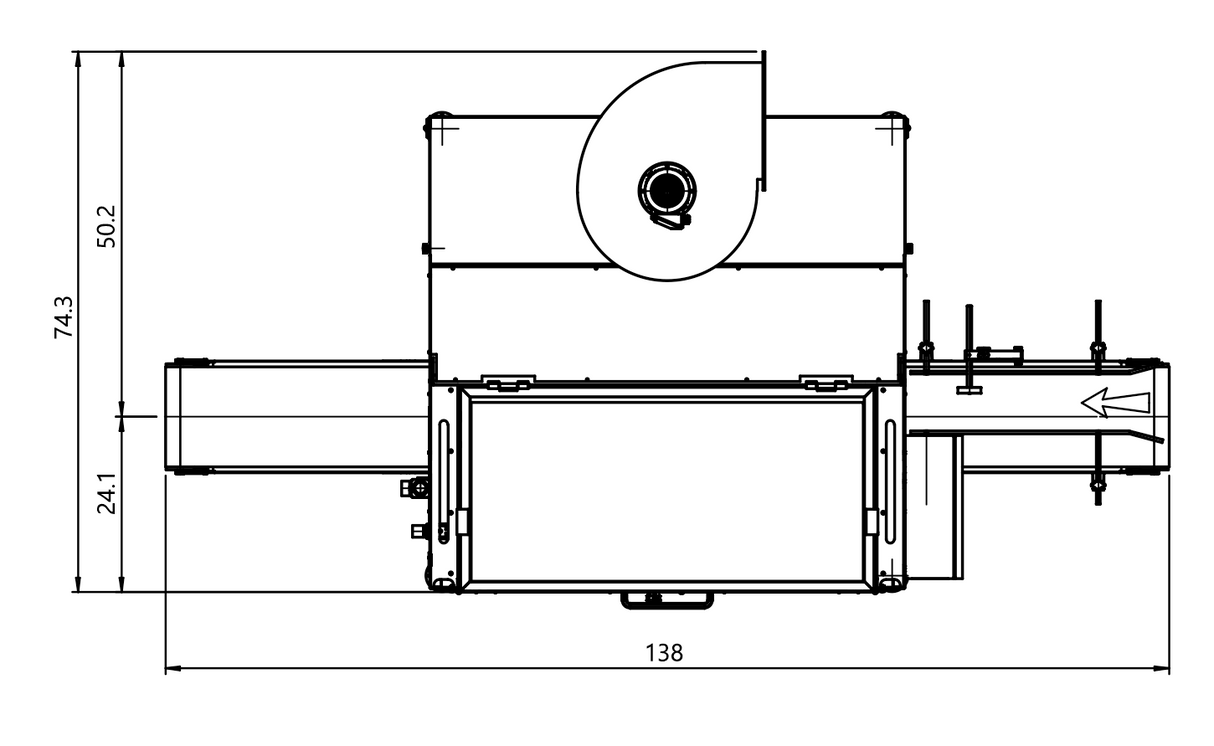

- Suction tower attached to the machine base on the rear part of the spraying booth, equipped with filter holder frames and electric fan; the filter holder frames can be extracted at the outfeed side of the machine, parallel to the feeding direction. Electric fan placed on the suction tower, with adjustable horizontal outlet (excluding exhaust pipes).

- Electric control placed frontally on the right side, on top of the feeding transport and commercial color RAL 6018 -pneumatic components placed on the wall at the out-feed of the cabin.

Machine will be delivered complete with assembled and tested mechanical, pneumatic and electric parts.

Machine with degree of protection: IP54; machine wiring according to EC standards. High Quality Components, European Origin.

Technical Data:

| External Length: | 11.5' |

| External Width: | 5.5' |

| Total Height: | 7.7' |

| Working Height: | 2.95' adjustable |

| Working Width: | 11.8" |

| Working Thickness: | 3.9" |

| Minimum Length of Piece: | 2.6' |

| Working Speed: | 65'-280' FPM |

| Suction: | 5400 mc/h (3178 CFM) |

| Power Supply: | 400V 50Hz |

| Installed Power: | 2,25 kw |

| Pneumatic Supply: | 5 bar min. (72.5 PSI) |

| Compressed Air Consumption: | see spray equipment (excluded) |

- Machine Paint: Black and Green (RAL 6018)

- Variable Conveyor Speed with inverter

- Number of Spray Tanks: 2

- Number of Gun Arms: 4 gun holder arms with adjustment clamps

- Number of Line Regulators for Compressed Air: 1 air

- Number of Pressure Regulators for Spraying: 2 Complete with Pressure

- Gauge and Button for Manual Control of the Guns

- Number of Gun Trigger Valves: 4

- Number of Separate Paint Circuits: 2 with High Pressure Recirculation Valve, galvanized fittings

- Electrical System according to Atex standards

- Input reading barrier photocell

- High pressure stainless steel paint circuits with recirculation valve -pressure switch on suction tower

- Conveyors and trays in stainless steel or polypropylene

- Paint equipment (pump and guns)

- Additional gun holder arm

- Quick coupling fittings for circuit change

- Without glass on the side walls of the cab

- Without removable box on wheels, but with removable front panel for cleaning and maintenance

- Without protruding pneumatic box, but with pneumatic system mounted on the wall at the exit of the booth, and internal protective casing

- Baskets for simplified filters

Stainless steel paint circuit with recirculating valve for machine:

High pressure circuit with stainless steel components for machine with 2 tanks, with recirculation pipe and external diverter valve, for feeding / recirculation switching.

Possibility of being able to feed guns on each tank; if not used on a tank, it is necessary to close the circuit on the specific tank, with an additional hose (not supplied).

Excluding connecting pipes to the guns.

Horizontal barrier photocell placed at the in-feed:

Barrier photocell, particularly suitable for thin, crooked profiles, or in all cases where contact with the profiles is not permitted.

This accessory replaces the wheel arm on the incoming conveyor belt.

This accessory requires a motorized preload transfer at the entrance.

Electrical system in compliance with ATEX standards for machine cabin:

Explosion proof electrical system to Atex standards only for the spray cabin of the machine.

The "ATEX" option includes:

ATEX-marked drive motor and fan motor

ATEX-marked fan with non-sparking characteristics

Coils of solenoid valves marked ATEX

Flame-Retardant Cables

Pressure Switch on the Suction Fan

Electrical installation in compliance with UL/CSA standards for profile spraying machine:

Electrical components in accordance with UL/CSA standards. Excluding certification of the electrical panel.

Pressure gauge on suction tower:

Pressure gauge (metro-manomer type) indicating the differential pressure and contact for clogged filters. Mounting and wiring included.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.