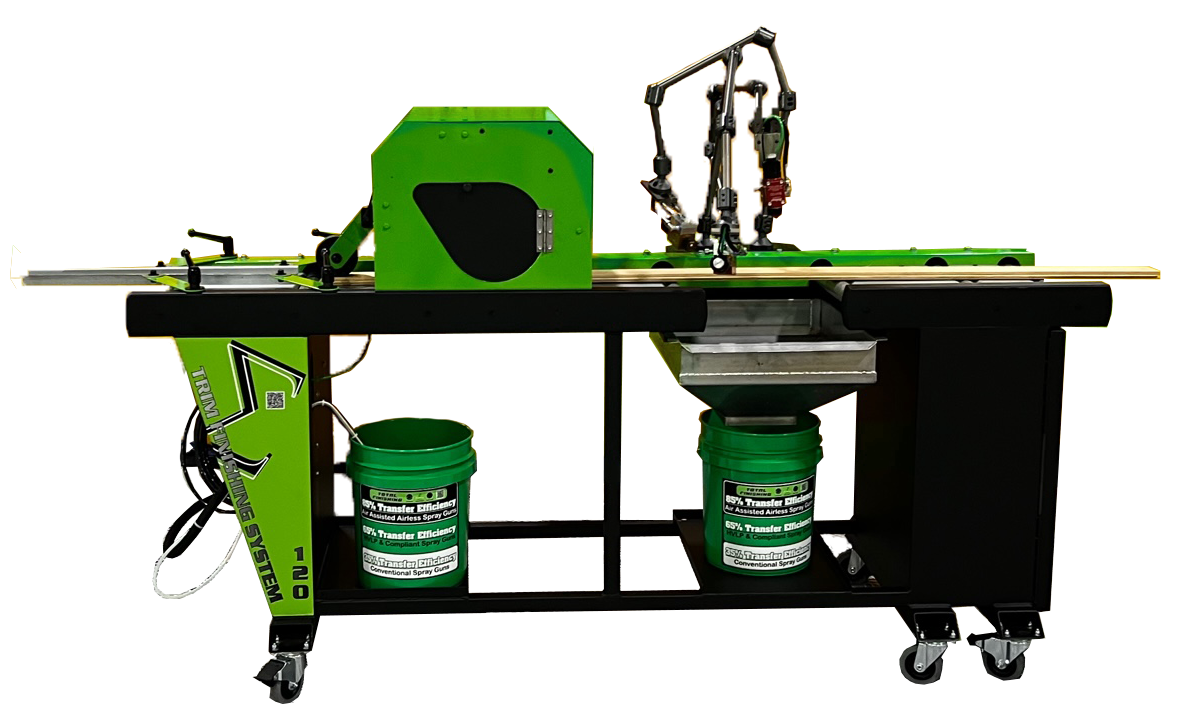

Trim Finishing System 120 Linear Spray Machine

tfs120 TFS-120

Trim Finishing System 120

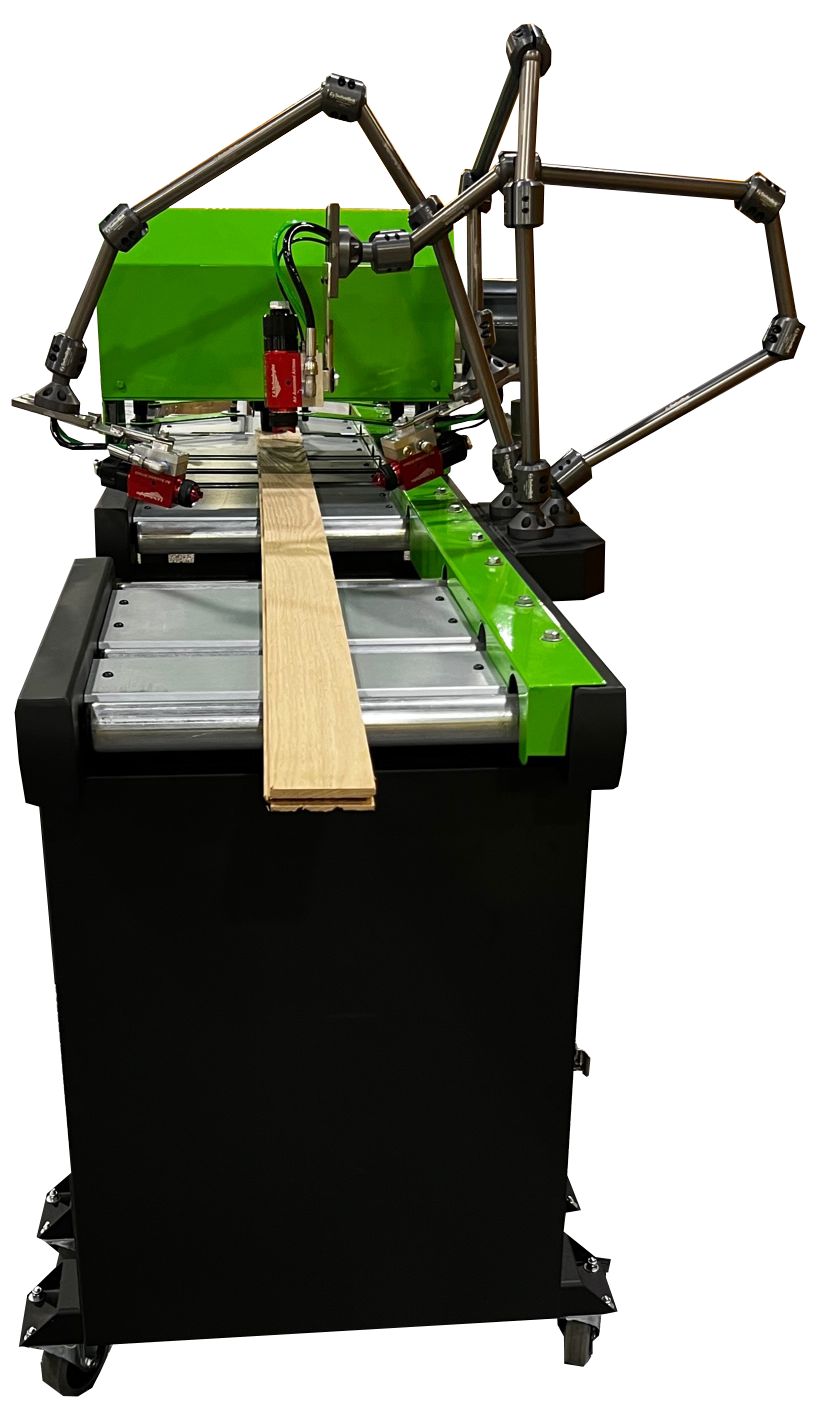

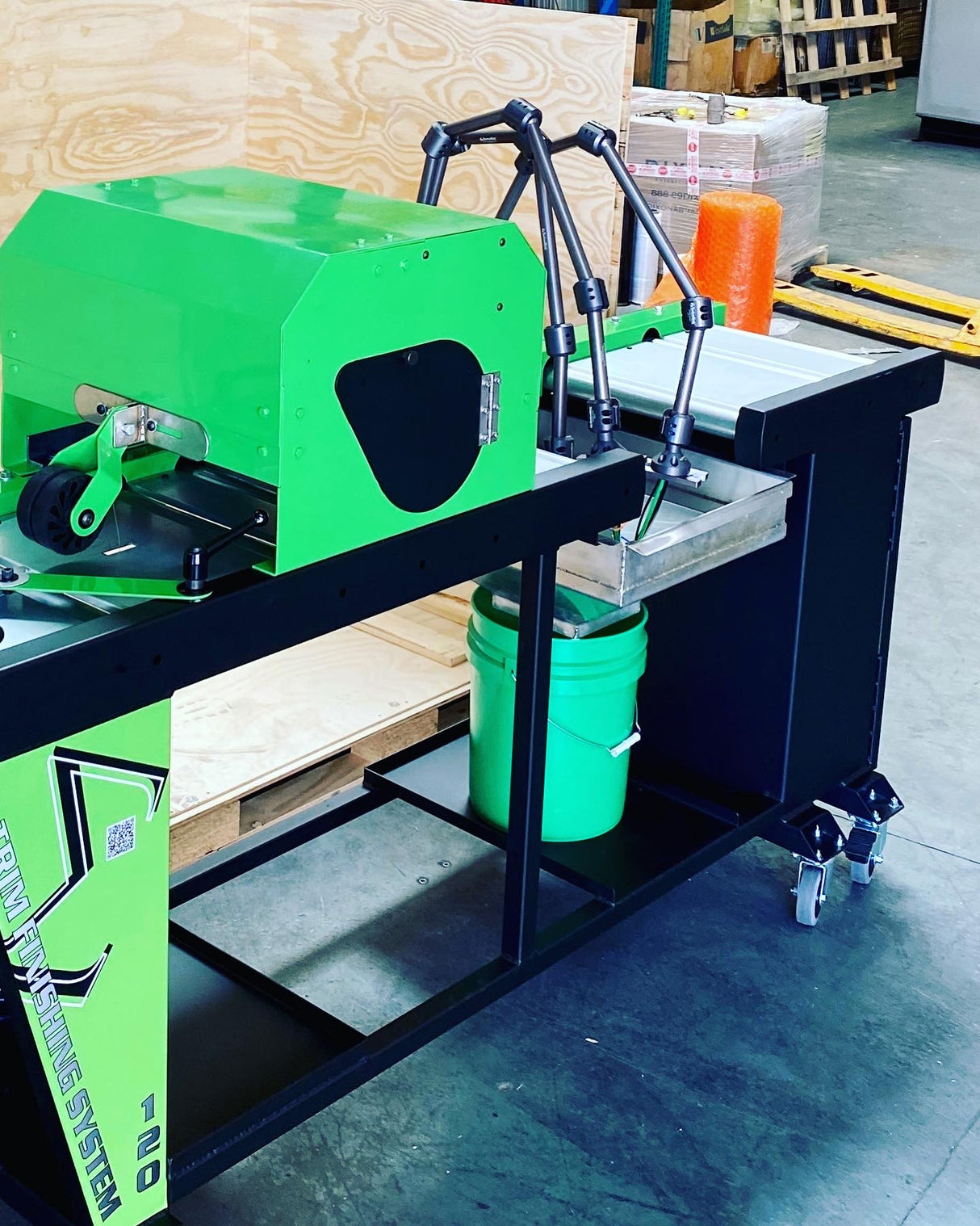

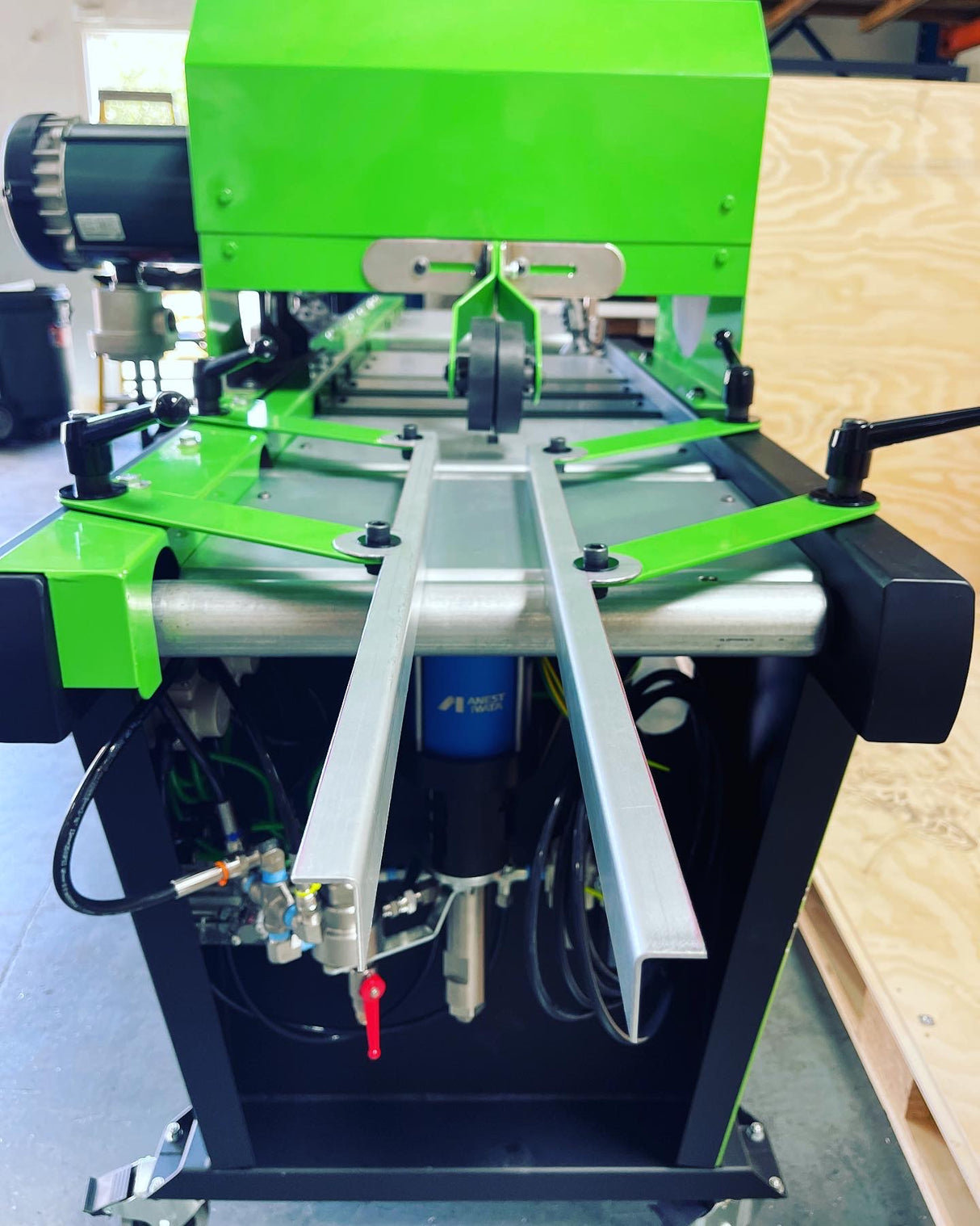

The powder-coated chassis and anodized articulating gun arms with mounts showcase exceptional durability and premium quality, ensuring years of reliable performance and customer satisfaction

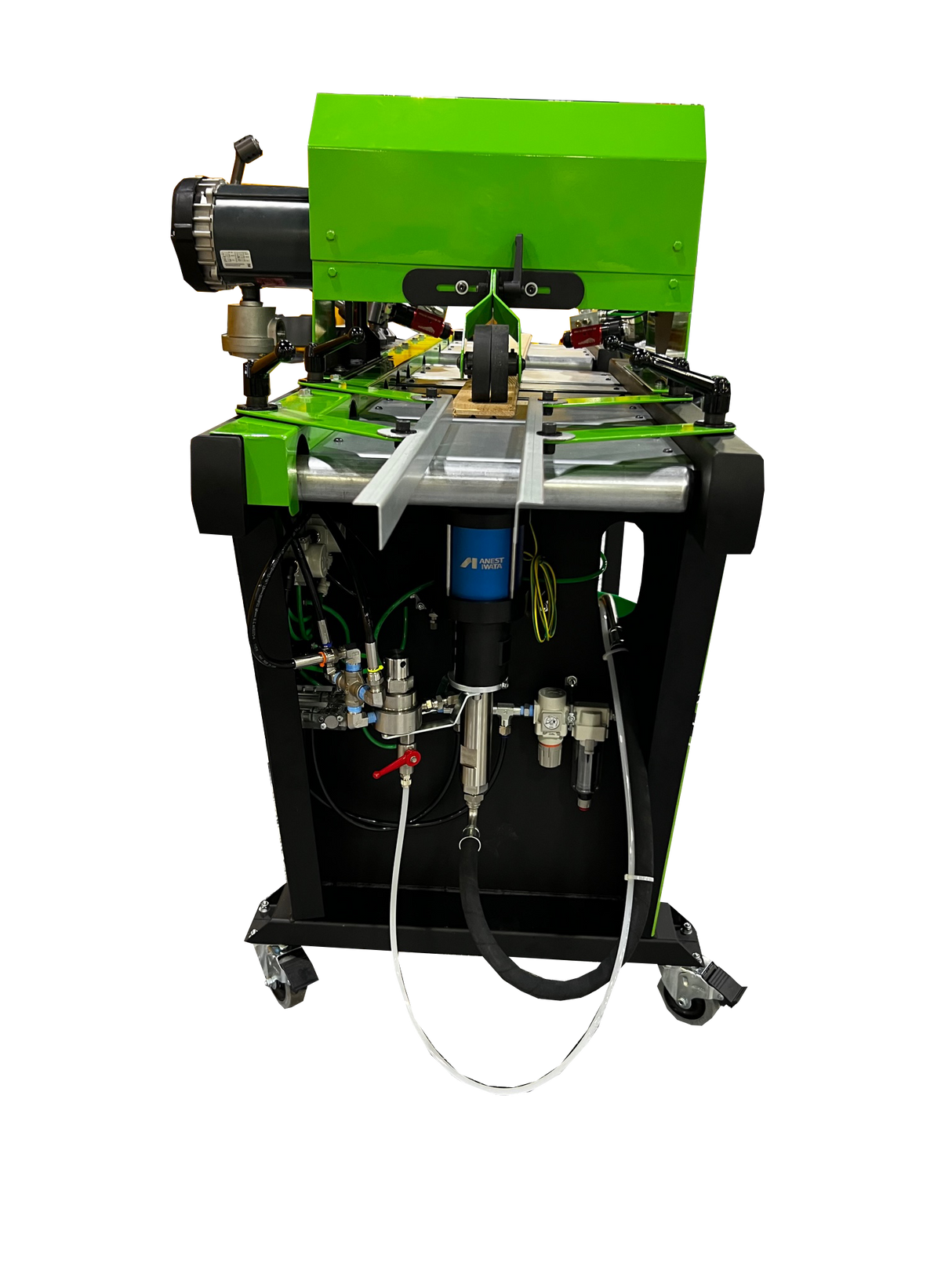

The 1-hp Class 1/Div2 Explosion Proof motor is equipped with a variable speed inverter which provides 110v single-phase plug-in convenience.

The TFS-120® is designed to accommodate 34” minimum lengths, and 12” maximum widths.

|

Hulk Conveyor™ Infeed / Outfeed Conveyor |

|

Total Finishing Double Head Brush Sander Twin Top Head Sanding Unit |

Operation and Setup of the TFS-120®:

The TFS-120® Highlights:

A Look Under the Hood of the TFS-120®:

The Guns:

The TFS-120® is equipped with three TFS Automatic VIPER-X® Air Assisted Airless Spray Guns, with the tip size of your choice for each gun. The standard we ship with (3) 06-094 tips (.411), one (1) for each automatic spray gun.

The automatic spray guns work in conjunction with an air logic controller, which controls the opening and closing operating times of the spray guns.

The spray guns are both solvent and waterborne-compatible and fully satisfies the California South Coast Air Quality Management Districts HVLP requirements.

Thanks to their simple operation and maintenance, TFS-120®’s guns do not require expert or skilled operators.

Paint Shelf:

The powder-coated paint supply shelf allows convenient access for loading 5-gallon coating containers. This also allows you to easily transport and move the portable system within your shop or on a job site.

The Pump:

Coating product is fed to the spray guns by means of the dependable Anest Iwata Icon 30:1 Heavy-Duty piston pump with a self-adjusting packing design. The design provides a 30:1 fluid ratio to compressed air pump supply. It is multi-gun capable and delivers material on demand at operating fluid pressures up to 210 bar/3045 psi. The stainless steel body is chemically compatible with today’s finishing materials and solvents.

Denibber:

The oscillating abrasive quick discs are, in just half a revolution, moving 120 mm sideways in one direction and back again in the second half of the revolution. Altogether the travel of the abrasive on the surface is more than 4”. This means that the fibers on the surface will be attacked alternately from the right and left sides up to 20 times per second. As a rule, the rpm will do more to the aggressiveness than the grit.

It should be understood that the TFS-120® denibber is not a sander per se. but works well for denibbing seal coats prior to top coating on the top side of trim pieces.

You can expect it to:

- Brush small fibers off the surface of the wood without creating new ones. This means the wood will look brighter.

- Break sharp edges. The edges still look sharp but the color pigments in the stain, sealer, or topcoat will stay on the edges and protect them instead of falling off.

- Used as a sealer “sander”, the discs not only smooth the surface but matte the sealer to make the topcoat adhere better.

Placed in the spraying zone of a functional spray booth, the booth’s face velocity offers sufficient protection against overspray pollution for the operator and the work area as well.

The mobility (it’s on wheels) provides roll-away storage convenience when not in use.

- Infeed Speed 0 to 150 Feet Per Minute

- Motors and Controls for 115V/60Hz/15amp

- Air Pressure 90psi

- Minimum Product Length 34”; Maximum Product Cross Section 12” x 3”

- (1) One Anest Iwata Icon 30:1 Stainless Steel Piston Pump

- (3) Three TFS Automatic VIPER-X® Air Assisted Airless Spray Guns w/Base, Cap, and Tip

- (1) One Graco High-Pressure Fluid Filter w/ 100 Mesh Screen

- (2) Two Regulators w/Gauges

- Single Head 1725 rpm Oscillating Denibber

- 1 HP Hazardous Location Motor and on-off Switch

- Computer-designed thru-flow funnel and overspray collection

- Variable Speed Control

- Air Logic Time Delay

- Zinc Plated Gun Arms

- Stainless Steel EZ Feeder Fence

- Requires a minimum of 12 CFM at 90 PSI of air to operate

- Overall Height 60”

- Overall Width 28”

- Overall Length 98”

- Weight 850 lbs.

- Shipping Weight 1125 lbs.

- Shipping Dimensions: 96 x 48 x 60

Total Finishing Systems, LLC warrants that all equipment sold hereby will be of the kind and quality described in this agreement. The equipment manufactured by Total Finishing Systems, LLC is guaranteed to be free from all latent defects in material and workmanship disclosed under normal use and service, and should any part thereof be found, within one year from the date of shipment, to be so defective at the time shipped, Total Finishing Systems,, LLC will repair or, at Total Finishing Systems,, LLC's option, replace said part. In the case of standard apparatus furnished, but not manufactured by Total Finishing Systems,, LLC, such as fans, motors, ovens, heaters, controls and light fixtures. Total Finishing Systems,, LLC extends to purchaser the same guarantee as is given by their respective manufacturers. Total Finishing Systems,, LLC is not required to provide equipment or meet performance specifications or standards not expressly set forth in this agreement. Total Finishing Systems, LLC's liability hereunder, however, is expressly limited to the materials furnished by it and does not extend to any damages to building, contents, products or persons. This warranty shall not apply to any of Total Finishing Solutions, LLC's apparatus which shall have been altered or repaired outside of Total Finishing Systems, LLC’s factory in any way so as, in Total Finishing Systems,, LLC's judgment, to affect its performance, nor which has been subjected to misuse, negligence, accident or improper installation. IT IS EXPRESSLY AGREED THAT THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF FITNESS OR MERCHANTABILITY, EXPRESS OR IMPLIED.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.