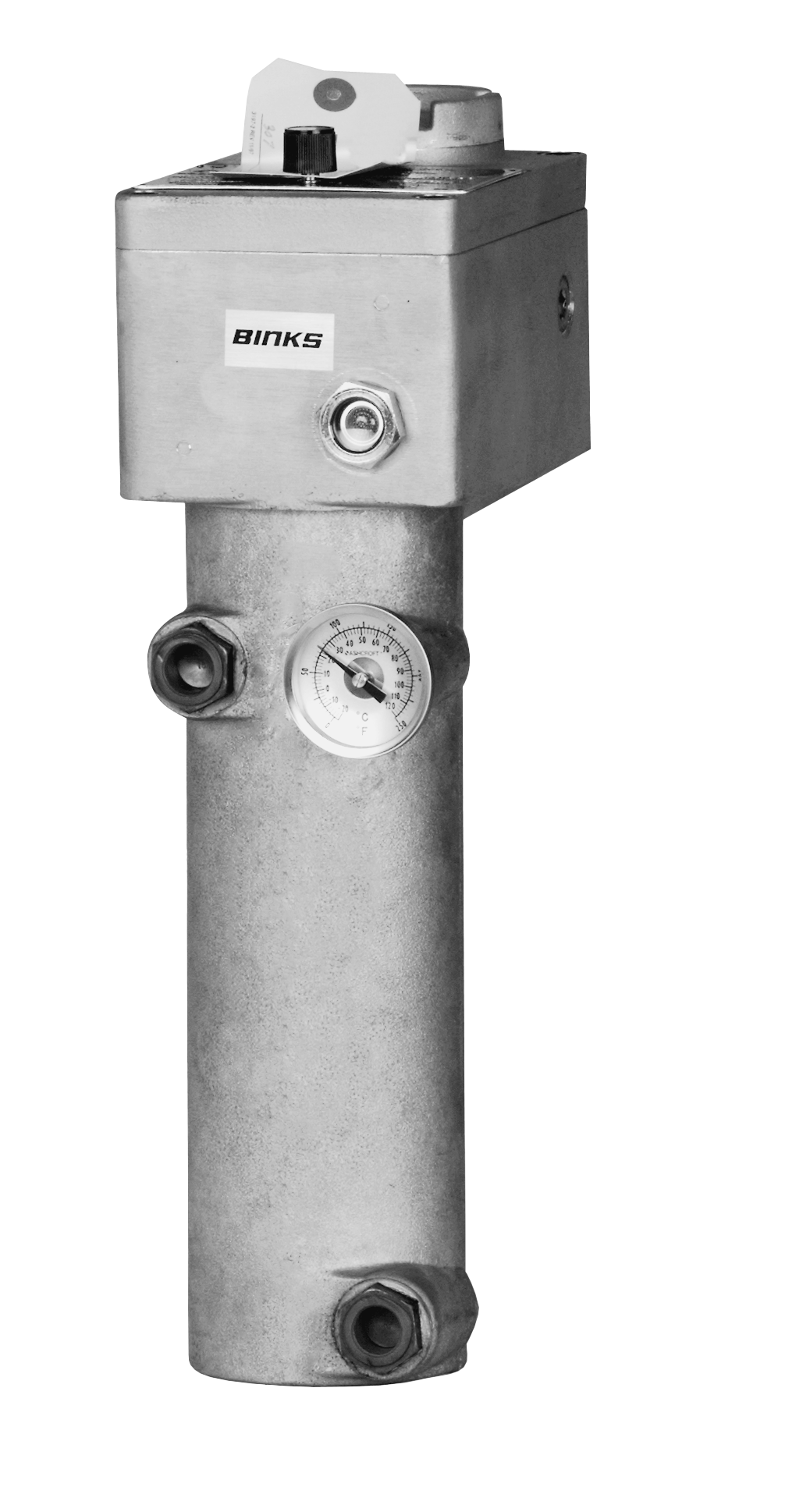

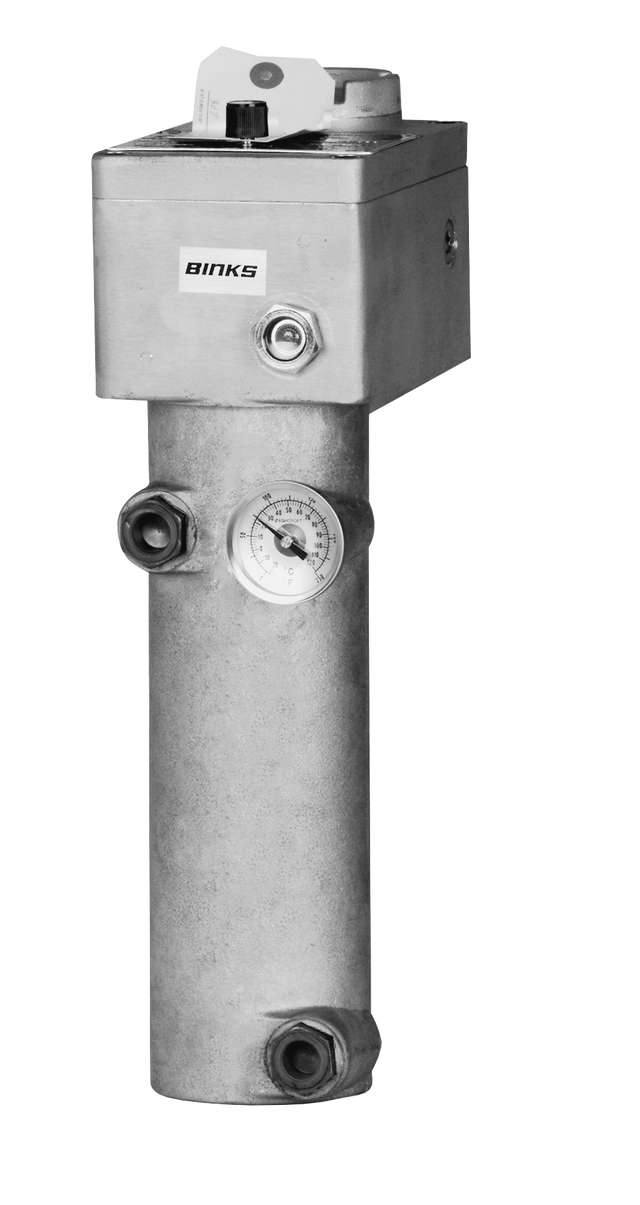

Binks Fluid Heater - Heater Only

Binks Fluid Heater - Heater Only

Manufacturer: Carlisle Binks

Part #: 83000X

Description: Stainless steel fluid heater models are wired for 120, 230 / 240, and 415 / 440-volt applications. The heating element is a 2000 watt cartridge type and is thermostatically controlled. The wiring, heating element, and thermostat are protected by a preset heat limiter.

High pressure, lightweight, explosion-proof. 5000psi capacity, Available in 3 voltages - 120 (16.6 AMPS), 240 (8.33 AMPS), 440 (4.5 AMPS), mounting bracket included.

Temperature control is a critical aspect of high-quality finishing. Temperature influences how easily the paint pumps, atomizes, and flows out. It affects how quickly the coating dries (or cures) and how hard the film becomes. Often the exact temperature at which something in the paint shop happens is less important than the consistency of the temperature. Let’s dig in with our FAQs.

What temperatures are important?

At least six temperatures are important enough to monitor:

- Paint

- Booth air

- Compressed air

- Bake ovens, if used

- Pretreatment chemicals, if applicable

- Substrate

Principle

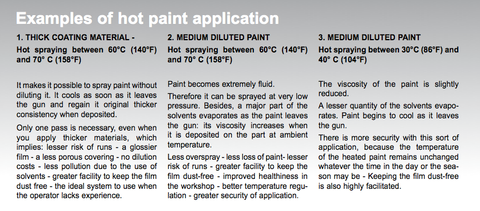

By raising the temperature of a fluid, you reduce its viscosity: for instance, heating paint up to 60° or 80° C will have the same result as using a solvent.

Hot paint spraying is also a good solution to maintain paints at a regular temperature, preserving them from the variations of temperature in a workshop all and every day.

- Regularity of efficiency

- Solvent savings

- Reduction of the risk of runs

- Viscosity

- Better finish quality

- Reduction of the rejects due to dirt

- Faster preparation

Apply more paint per pass

As the discharged paint exits the gun, two factors raise the viscosity of the paint. The accelerated evaporation of the hot solvents and the cooling of the resin. The net effect is the ability to apply more paint per pass without runs.

Process

Cold paint is discharged into the heater (4) under the action of pressure. It is instantly warmed to the selected heat and reaches the spray gun (3) after passing through the filter (8) at a similar temperature.

What happens if the paint is too warm or too cold?

Cold paint will be too viscous (too thick). It will pump, atomize and flow out with difficulty. Also, the rate of solvent loss from cold paint on the part will be reduced. The retained solvent will keep the paint runny, and sagging may result. This effect usually overcomes the reduced flow from higher viscosity. The result is more sags on cold mornings. The retained solvent may also lead to popping in the oven.

Warm paint flows too easily. When warm, more paint than is needed will flow at a given pump setting. Atomization will require more air pressure and a larger paint cloud will form. The result will be wasted paint and more mess.

In some cases, paint temperature variation may influence the color.

How closely should the paint temperature be held?

This is not an easy-to-answer question. It depends on the solvent blend (fast or slow) and the skill of the operator. Skillful painters can compensate for considerable variation in temperature, line speed, solvent blend, etc.

A manual application can usually accommodate a plus or minus 5 degrees Fahrenheit temperature variation without much problem. Automatic applicators work best if the paint varies no more than 3 degrees Fahrenheit from the recommended value.

How can I control the paint temperature?

The best option is to use a paint heater.

How do paint heaters work?

There are at least four ways to heat paint before application:

1. Non-circulating (dead-ended) systems use a warm liquid pumped through a special hose inside the paint hose. The circulating warm liquid is heated electrically and it warms the paint.

2. Circulating systems usually use an electrical resistance element in a cast aluminum body through which the paint is pumped. This is the most common approach to heating paint.

3. Sometimes an electric liquid-to-liquid system heat exchanger is used to heat the paint. These systems are somewhat complex, but they can be used to cool as well as heat. That might be a useful feature for catalyzed systems.

4. You can also use an electric drum or pail heater. This heater uses a belt that wraps around the drum. Plugin and set the thermostat to what you want.

Won’t the paint viscosity drop if I heat the paint?

Correct — but the viscosity will be consistent. If the viscosity is too low, you can simply spray at higher solids. In fact, some high-solid paints are heated mainly to drop the viscosity into a sprayable range. The paint supplier may want to change the solvent blend to accommodate a higher spray temperature.

What’s the problem if the parts are too warm or too cold?

Cold parts present two problems. The first is that they cool the paint, with the result being that the paint may sag in the booth or pop in the oven (due to retained solvent). Second, if the parts are cool enough, they may condense water vapor from the air and coat the surface with a film of water prior to painting. The water film reduces adhesion and may cause the paint to slide off the surface.

Warm parts may dry the paint droplets as they strike the surface and prevent good leveling. With waterborne warm parts may reduce the paint viscosity and lead to sags.

How much hotter or colder than the paint can the parts be?

That’s not an easy question to answer. It depends on the solvent blend in the paint and the humidity of the air. Five or 10 degrees Fahrenheit is usually not a problem.

Specifications:

| Part No |

Max. Working Pressure |

Temp Range | Wetted Parts | Voltage | Amperage | Mounting Hardware | Wattage | Service Form |

| 830000 | 5000 psi | 60-250 Def F | Stainless Steel | 120 vac | 16.6 amps | Included | 2000 Watts | 83000X |

| 830001 | 5000 psi | 60-250 Def F | Stainless Steel | 240 vac | 8.33 amps | Included | 2000 Watts | 83000X |

| 830002 | 5000 psi | 60-250 Def F | Stainless Steel | 440 vac |

4.5 amps |

Included | 2000 Watts | 83000X |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.