El recubrimiento en polvo se ha convertido en una opción de acabado popular para diversas industrias, ya que proporciona un acabado duradero y de alta calidad a una amplia gama de productos. A medida que las empresas exploran formas de optimizar sus procesos de producción, la decisión de implementar el recubrimiento en polvo en forma interna o subcontratarlo se convierte en una consideración fundamental. En este blog, analizaremos en profundidad las ventajas y desventajas de ambas opciones, centrándonos en factores clave como el control, la flexibilidad, la calidad y la rentabilidad.

Ventajas de incorporar el recubrimiento en polvo en la empresa:

- Mayor control y flexibilidad:

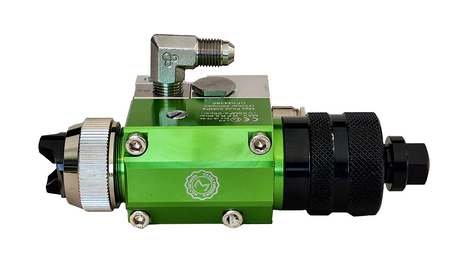

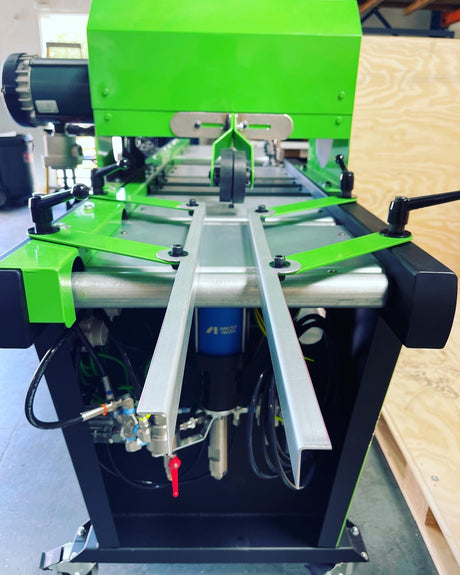

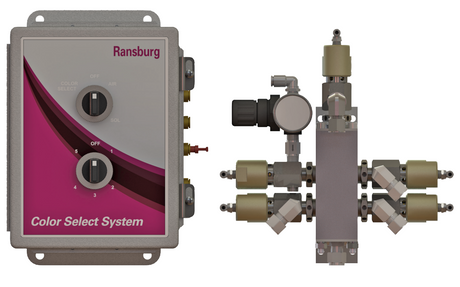

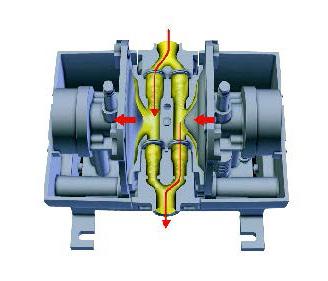

- Cuando una empresa incorpora el recubrimiento en polvo a sus instalaciones, obtiene un control directo sobre todo el proceso de recubrimiento. Esto incluye la selección del polvo, el ajuste de los parámetros de aplicación y la garantía del control de calidad. Este nivel de control permite una mayor flexibilidad para adaptarse a los requisitos específicos del proyecto y realizar ajustes inmediatos para satisfacer las demandas cambiantes.

- Flujo de trabajo de producción optimizado:

- La integración de recubrimientos en polvo en la planta puede optimizar el flujo de trabajo de producción. Con instalaciones de recubrimiento en el lugar, los productos pueden pasar sin problemas de la fabricación al acabado, lo que reduce los plazos de entrega y mejora la eficiencia general. Esta integración elimina la necesidad de transporte entre instalaciones, lo que minimiza el riesgo de daños durante el transporte.

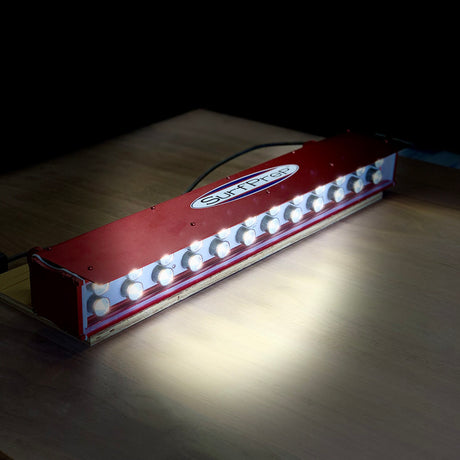

- Seguro de calidad:

- Mantener los estándares de calidad es fundamental en cualquier proceso de fabricación. El recubrimiento en polvo interno permite realizar controles de calidad inmediatos y en tiempo real, lo que garantiza que los productos cumplan siempre con las especificaciones de calidad y acabado deseadas. Este nivel de supervisión es crucial para las industrias en las que la precisión y el cumplimiento de los estándares no son negociables.

- Ahorro de costes a largo plazo:

- Si bien la inversión inicial en equipos y capacitación puede ser significativa, el recubrimiento en polvo en la empresa puede generar ahorros de costos a largo plazo. Con el control del proceso, las empresas pueden optimizar la eficiencia, reducir los desechos y negociar mejores acuerdos sobre las materias primas, lo que en última instancia contribuye a una operación más rentable.

Desventajas de incorporar el recubrimiento en polvo en la empresa:

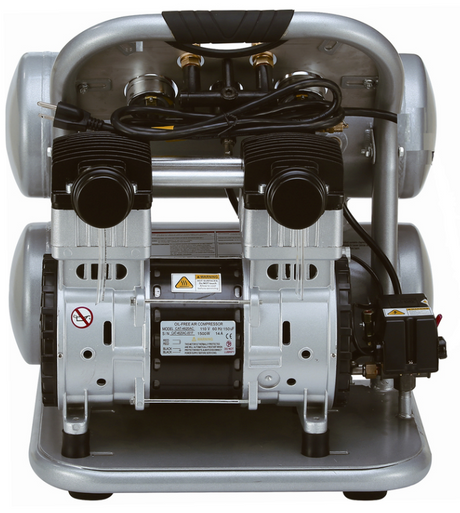

- Inversión de capital inicial:

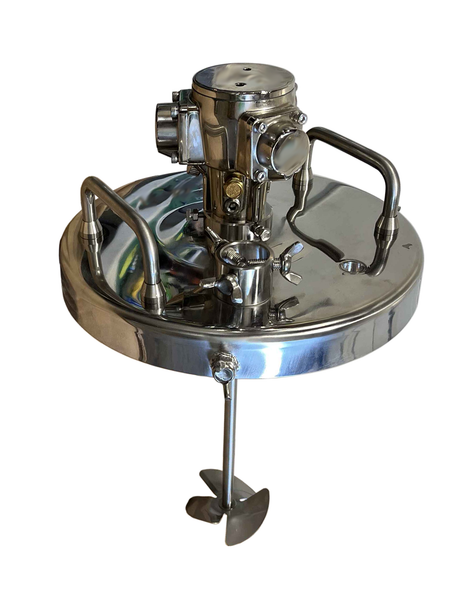

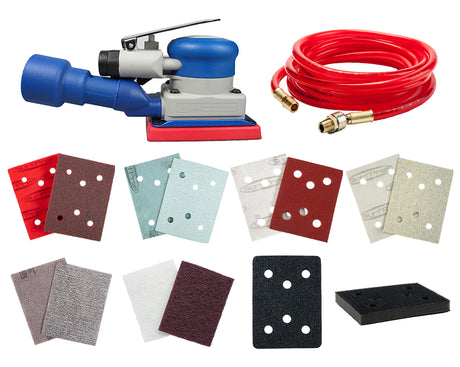

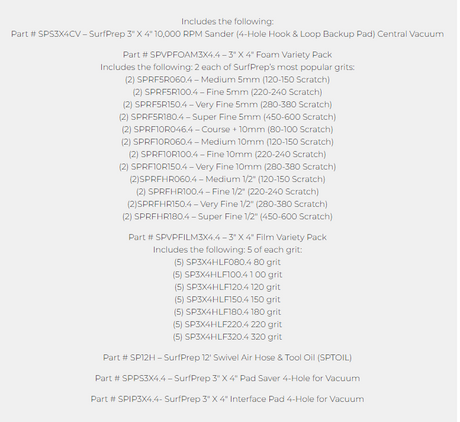

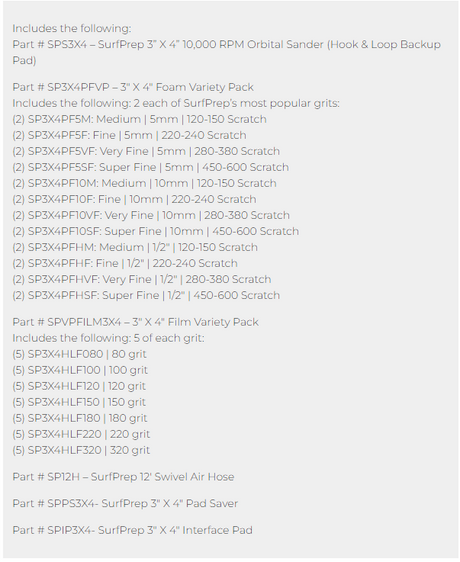

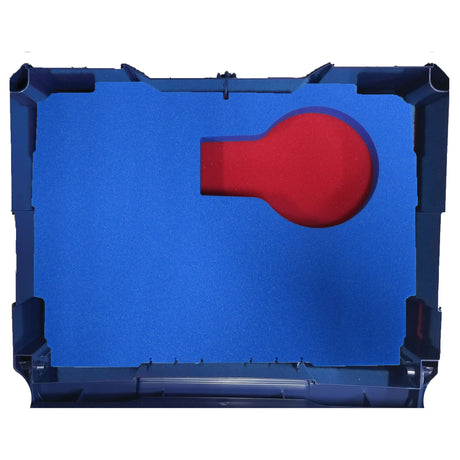

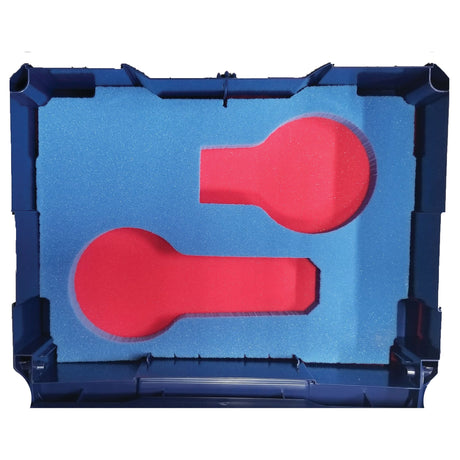

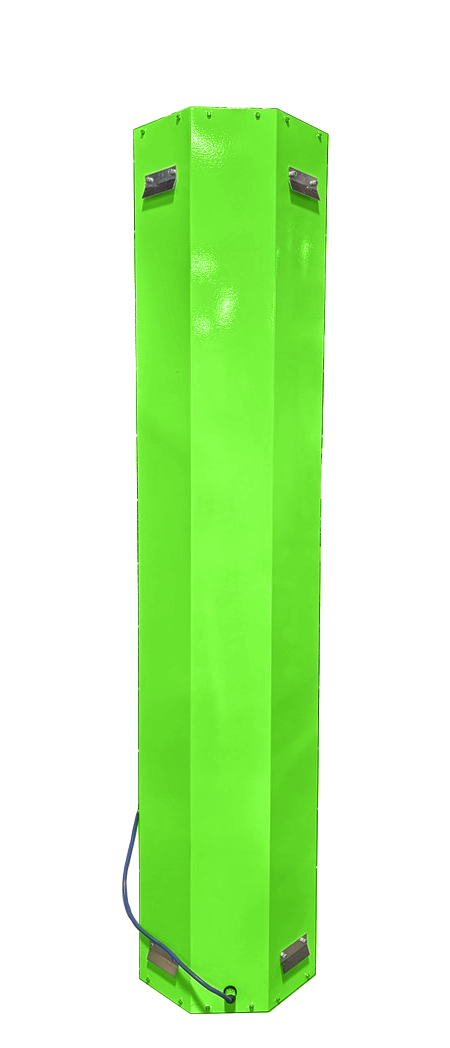

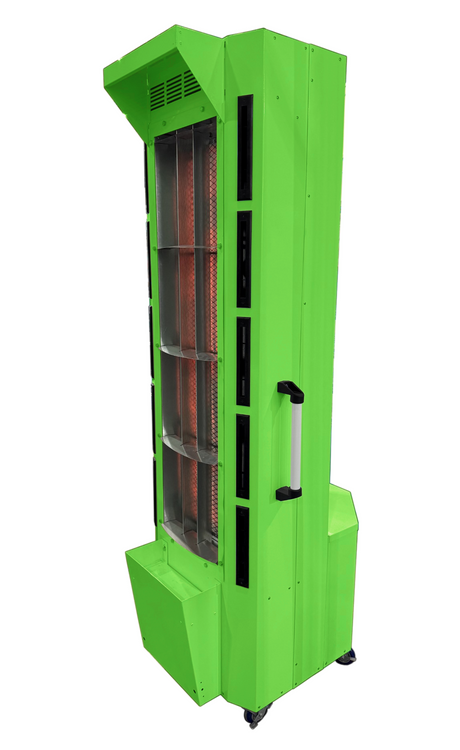

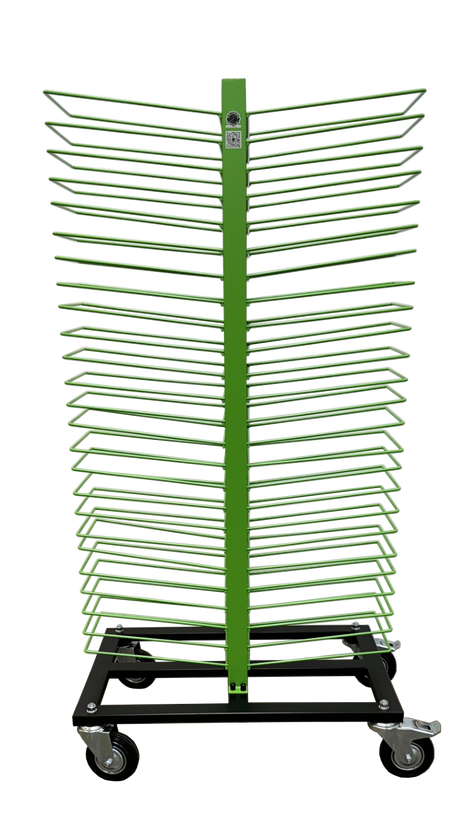

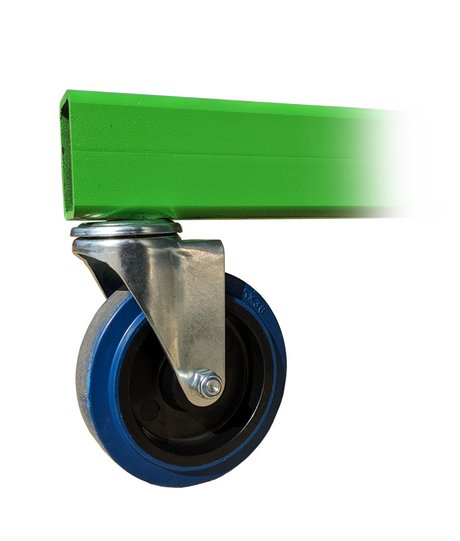

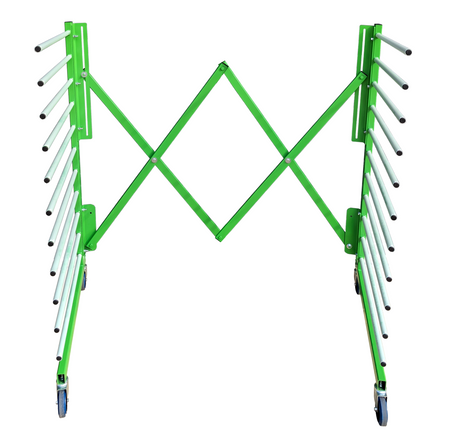

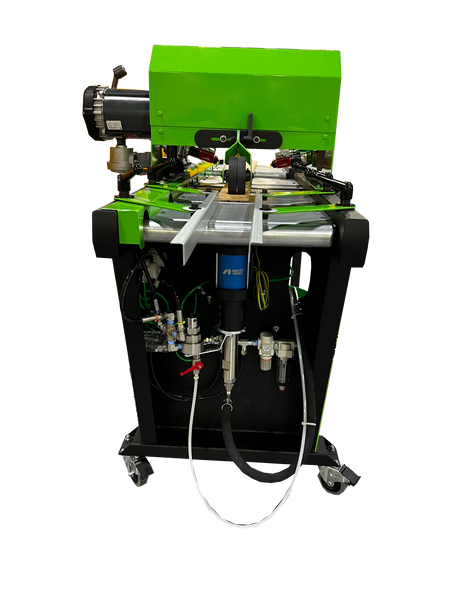

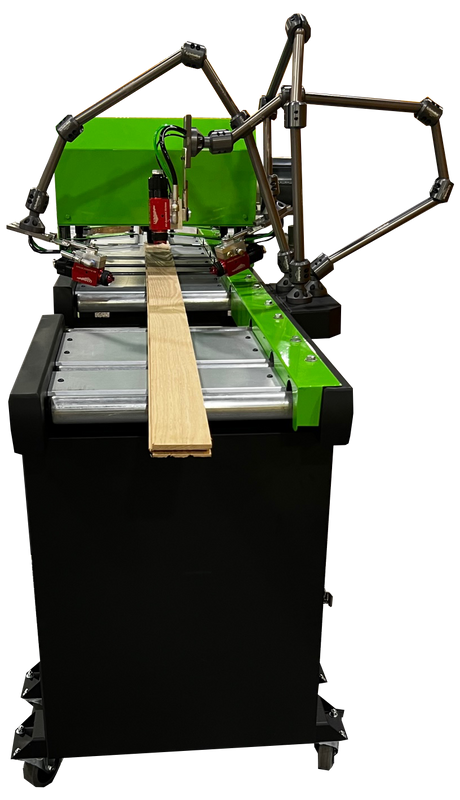

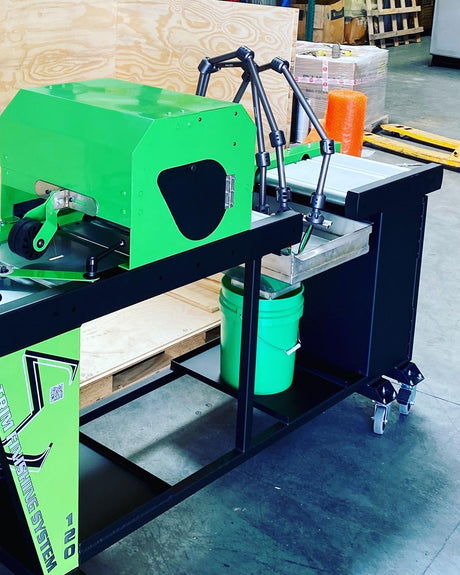

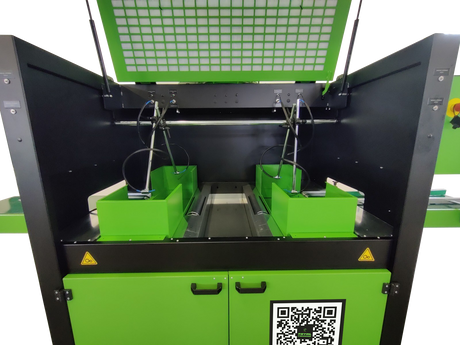

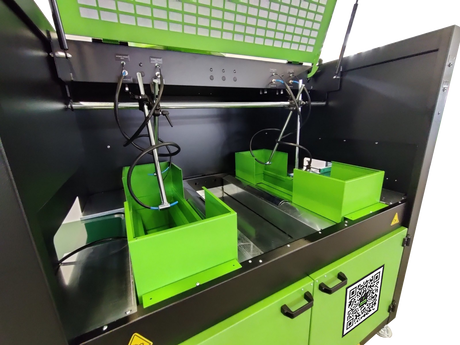

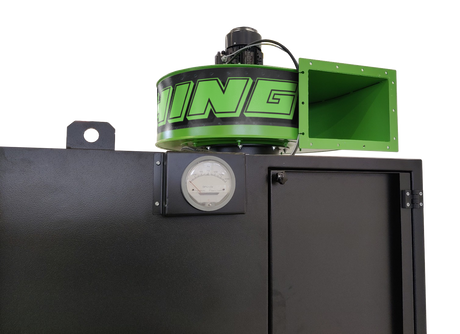

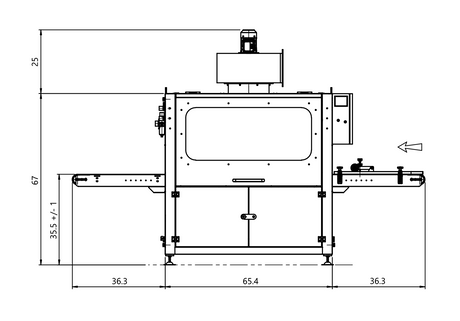

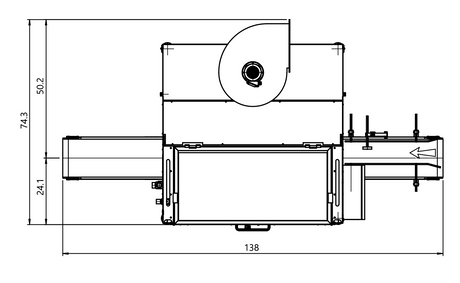

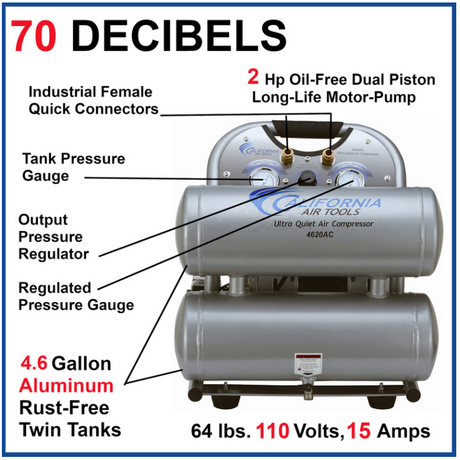

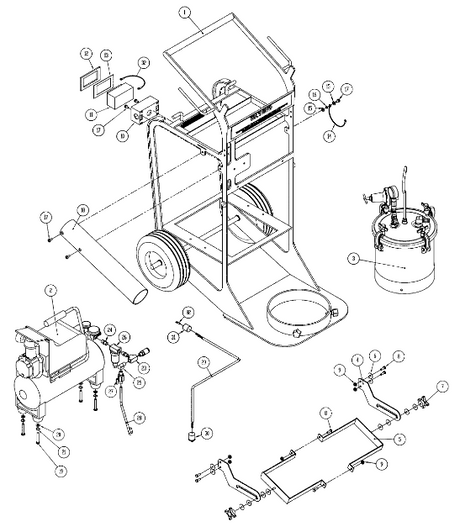

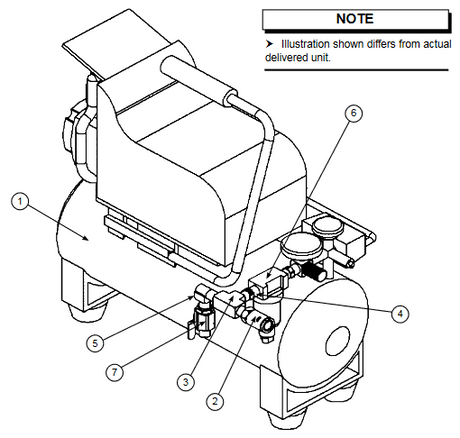

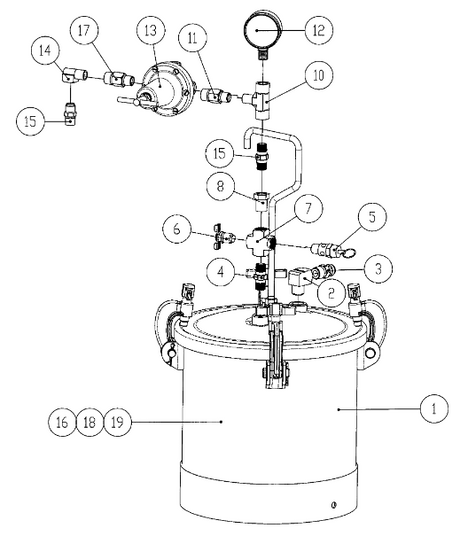

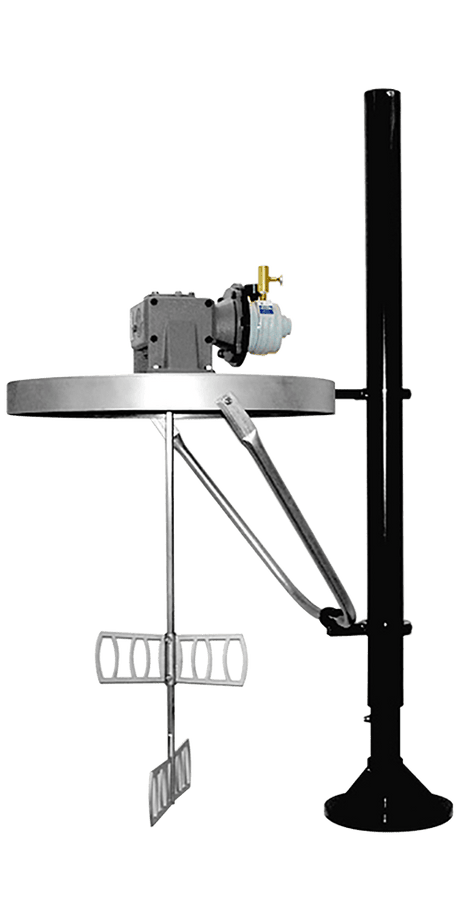

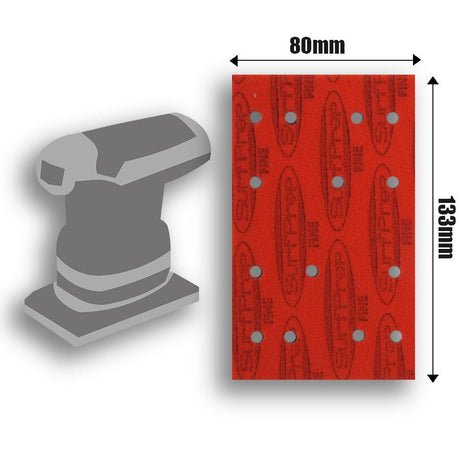

- Una de las principales barreras para implementar el recubrimiento en polvo en la empresa es la inversión de capital inicial requerida. La compra del equipo necesario, como una cabina de recubrimiento en polvo, un horno de curado y herramientas de aplicación, puede suponer un coste inicial considerable que puede no ser viable para las pequeñas o medianas empresas. Total Finishing Solutions ofrece financiación para que una empresa pueda realizar pagos reducidos a lo largo del tiempo.

- Experiencia y Formación:

- Para operar un sistema de recubrimiento en polvo de manera eficaz se requieren conocimientos y experiencia especializados. Las empresas que se aventuran a realizar recubrimientos en polvo en sus propias instalaciones deben invertir en la capacitación de su personal para garantizar técnicas de aplicación, mantenimiento y resolución de problemas adecuados. Esta curva de aprendizaje puede llevar mucho tiempo y afectar la productividad inicial.

- Costos de mantenimiento y operación:

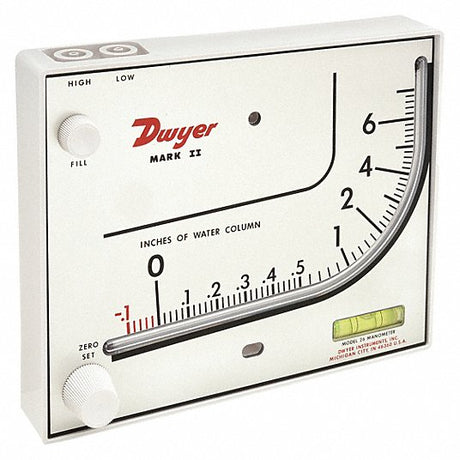

- Además de la inversión inicial, se deben tener en cuenta los costos operativos y de mantenimiento continuos. El mantenimiento regular de los equipos y los hornos de curado, junto con el costo de la electricidad y los materiales de recubrimiento en polvo, pueden contribuir a los gastos operativos generales.

Ventajas de subcontratar proyectos de recubrimiento en polvo

- Rentable para tiradas pequeñas:

- La subcontratación de proyectos de recubrimiento en polvo puede resultar rentable para empresas con producciones esporádicas o pequeñas. En lugar de invertir en instalaciones internas, las empresas pueden aprovechar los servicios de proveedores de recubrimientos especializados y pagar solo por los servicios que necesitan.

- Acceso a Experiencia Especializada:

- Los proveedores de servicios de recubrimiento en polvo suelen poseer conocimientos y experiencia especializados. La subcontratación permite a las empresas aprovechar estos conocimientos sin necesidad de una formación exhaustiva del personal interno. Esto resulta especialmente beneficioso para las empresas con recursos limitados para la formación y el desarrollo.

- Escalabilidad:

- La subcontratación ofrece escalabilidad, lo que permite a las empresas ajustar fácilmente su capacidad de recubrimiento en función de las fluctuaciones en las demandas de producción. Esta flexibilidad puede resultar ventajosa para gestionar los períodos pico sin necesidad de disponer de capacidad excedente durante los períodos de menor actividad.

Desventajas de subcontratar proyectos de recubrimiento en polvo

- Control y supervisión limitados:

- La principal desventaja de la subcontratación es el reducido nivel de control sobre el proceso de recubrimiento. Las empresas pueden tener una influencia limitada en la selección de materiales, técnicas de aplicación y procesos de control de calidad, lo que puede dar lugar a variaciones en el producto final.

- Dependencia de proveedores externos:

- Depender de proveedores externos para el recubrimiento en polvo hace que las empresas sean vulnerables a interrupciones en la cadena de suministro. Problemas como demoras en la producción, inconsistencias de calidad o cambios en las capacidades del socio de subcontratación pueden afectar significativamente el cronograma de producción general.

- Riesgos de transporte y manipulación:

- El envío de productos hacia y desde una instalación de recubrimiento externo presenta el riesgo de daños durante el transporte y la manipulación. Los productos delicados o grandes pueden ser más susceptibles a rayones, abolladuras u otros defectos, lo que puede comprometer la calidad del acabado final.

Consideraciones de costos para recubrimientos en polvo internos y subcontratados

En casa:

- Inversión de capital:

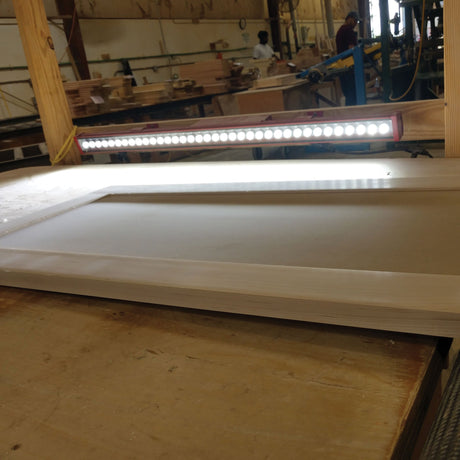

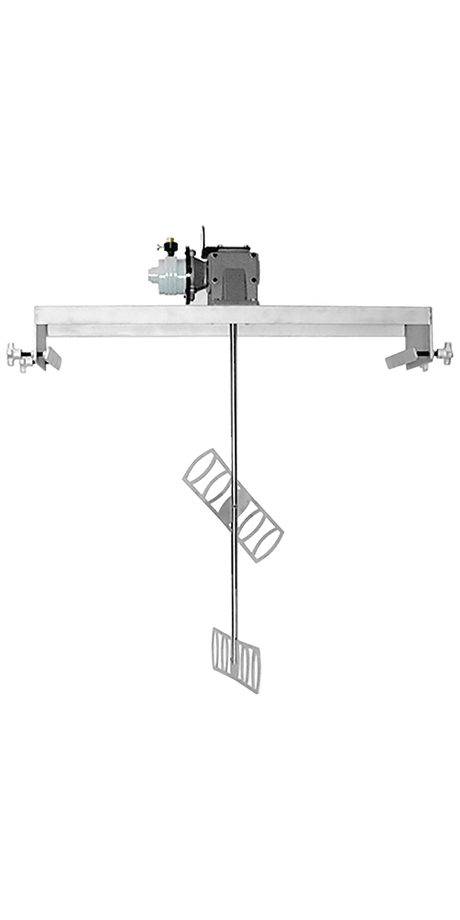

- La inversión inicial en equipos, como cabinas de recubrimiento en polvo , hornos de curado y herramientas de aplicación, puede ser considerable. Esto incluye tanto la compra del equipo como las modificaciones necesarias en las instalaciones.

- Costos operacionales:

- Los costos operativos continuos incluyen electricidad, mantenimiento de equipos y compra de materiales de recubrimiento en polvo. Si bien estos costos se distribuyen en el tiempo, contribuyen al costo total del recubrimiento en polvo interno.

- Costos laborales:

- El costo de la mano de obra calificada es un factor importante, considerando la necesidad de personal capacitado para operar y mantener el sistema de recubrimiento en polvo.

Subcontratado:

- Costos del servicio:

- La subcontratación implica pagar una tarifa de servicio al proveedor del revestimiento, que puede calcularse en función de factores como el tamaño y la complejidad del proyecto. Esta tarifa normalmente cubre el costo de mano de obra, materiales y gastos generales del servicio de revestimiento.

- Costos de envío:

- Las empresas deben tener en cuenta el costo de envío de los productos hacia y desde la planta de recubrimiento. Esto puede variar según la distancia y el método de transporte, lo que contribuye a los gastos generales de subcontratación.

- Medidas de control de calidad:

- Si bien algunos proveedores de subcontratación pueden incluir medidas de control de calidad en sus tarifas de servicios, las empresas pueden optar por implementar controles adicionales, lo que podría generar costos adicionales.

En el proceso de toma de decisiones entre la incorporación del recubrimiento en polvo a la empresa o su subcontratación, las empresas deben sopesar cuidadosamente las ventajas y desventajas de cada opción. La elección depende de varios factores, entre ellos el volumen de producción, la complejidad del producto, las limitaciones presupuestarias y la necesidad de controlar el proceso de recubrimiento.

El recubrimiento en polvo interno ofrece un control, una flexibilidad y un ahorro de costes a largo plazo incomparables, pero requiere una inversión inicial significativa y gastos operativos constantes. La subcontratación, por otro lado, ofrece soluciones rentables para tiradas pequeñas, acceso a conocimientos especializados y escalabilidad, pero conlleva la desventaja de un control limitado y una posible dependencia de proveedores externos.

En última instancia, la decisión debe estar en línea con los objetivos estratégicos y los recursos de la empresa. Las empresas que buscan un control total, personalización y beneficios de costos a largo plazo pueden considerar que el recubrimiento en polvo interno es una inversión acertada. Por el contrario, aquellas que priorizan la flexibilidad, la rentabilidad para tiradas pequeñas y evitan grandes costos iniciales pueden considerar que la subcontratación es una opción más adecuada. Como ocurre con cualquier decisión empresarial, un análisis exhaustivo de las necesidades y circunstancias específicas es crucial para tomar una decisión informada que se alinee con el éxito general de la empresa.

Para obtener ayuda con su decisión, comuníquese con nuestros expertos en TotalFinishingSystems.com .