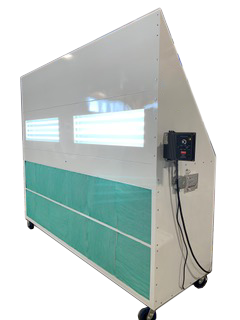

Paint Spraying Mobile Filter Wall

Paint Spraying Mobile Filter Wall

Manufacturer: Total Finishing

Part Number: TFS-MOBILE-PREP

Description: Prevents overspray, odors, and VOC spread for a cleaner work environment. The Mobile Prep Station is a versatile, portable finishing workstation that enhances efficiency and productivity in painting and refinishing tasks. Its self-contained, non-venting recirculation design allows for maximum flexibility, making it easy to use in auto body repair, aerospace, manufacturing, maintenance, woodworking, and more. Designed for convenience and ease of use, it ships as a complete, stand-alone system—simply plug it in and get to work.

Heavy Duty Construction:

All of our single wall prep stations are made with premium 18 ga. Zinc galvanized steel panels, companion flanged and pre-punched at 6" on center for easy assembly with 1/4" nuts and bolts. Single Wall. Better airflow, lighting, and strength because of gabled roof design. TOP-Designed to meet the requirements of EPA’s 6H Paint Rule (40CFR63 Subpart HHHHHH), Total Finishing prep stations provide a controlled environment for sanding, priming and limited painting. When priming and painting, the amount of material sprayed shall not exceed one gallon in an eight-hour period.

-

Fans & Motors: 208-240V, 3 Phase standard. Please call if alternative electrical is required.

- (1) - 30” 12,900 CFM Tube-axial fan.

- (1) - 2HP-3PH-240v motor High capacity exhaust & intake Directly connected to turbine

- (1) - 30” 12,900 CFM Tube-axial fan.

-

Filters:

- POST EXHAUST FILTERS:20'' X 25'' PAINT POCKETS

- EXHAUST FILTERS: 20'' X 20'' FIBER GLASS FILTERS

- POST EXHAUST FILTERS:20'' X 25'' PAINT POCKETS

-

Lighting:

- (2) upper horizontal light fixtures Energy efficient ballast 120V 60Hz. 4' light fixtures with 4 LED lamps

-

Dimensions:

- 3' Long x 10' Wide x 8' High

Additional Booth Options:

- White Powder Coated Finish - ultra white inside and out of the spray booth. cover all wall panels, doors frame, floor channels and ceiling panels.

- UL Listed Control Panel with Emergency Stop

Additional Accessories:

- Control VFD - Brings together or combines motor control devices and circuit protection. The control panel protects these devices from moisture, corrosion, dust, and other damage.

Disclaimer: Fire systems need to cover all working areas and ducting exhaust vents. Fire systems need to be installed be NFPA no 17. The customer is responsible for all required permits (mechanical, electrical, fire, air quality, etc., unless specified), applicable taxes, freight, off-loading, storage, and disposal costs. Additional responsibilities include mounting and connecting control panels, providing adequate electrical and gas supply, electrical wiring, gas and air piping, fire protection (if required), site preparation, equipment receiving, and forklift use unless otherwise specified.

Ships by Truck Freight.

FOB California - You will be contacted with a freight quote or you can arrange your own freight. Forklift required at the time of delivery.

Manufacturers Warranty

TFS warrants that all equipment sold hereby will be of the kind and quality described in this agreement. The equipment manufactured by TFS is guaranteed to be free from all latent defects in material and workmanship disclosed under normal use and service, and should any part thereof be found, within one year from the date of shipment, to be so defective at the time shipped, TFS will repair or, at TFS's option, replace said part. In the case of standard apparatus furnished, but not manufactured by TFS, such as fans, motors, ovens, heaters, controls, and light fixtures. TFS extends to the purchaser the same guarantee as is given by their respective manufacturers. TFS is not required to provide equipment or meet performance specifications or standards not expressly set forth in this agreement. TFS's liability hereunder, however, is expressly limited to the materials furnished by it and does not extend to any damages to buildings, contents, products, or persons. This warranty shall not apply to any of TFS's apparatus which shall have been altered or repaired outside of TFS's factory in any way so as, in TFS's judgment, to affect its performance, nor which has been subjected to misuse, negligence, accident or improper installation. IT IS EXPRESSLY AGREED THAT THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES OF FITNESS OR MERCHANTABILITY, EXPRESS OR IMPLIED.

All paint spray booths and spray booth accessories — including but not limited to ducting, lighting, and control panels — are custom made to order and are not refundable

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.