Binks IntelliFlow RF2+ Automatic Multi-Component Proportioner - Low Pressure

RF2+ Automatic Multi-Component Metering, Mixing, And Flow Control Proportioner - Low Pressure

Manufacturer: Binks

Part Number: RF2P-LA2-XX-XX-X

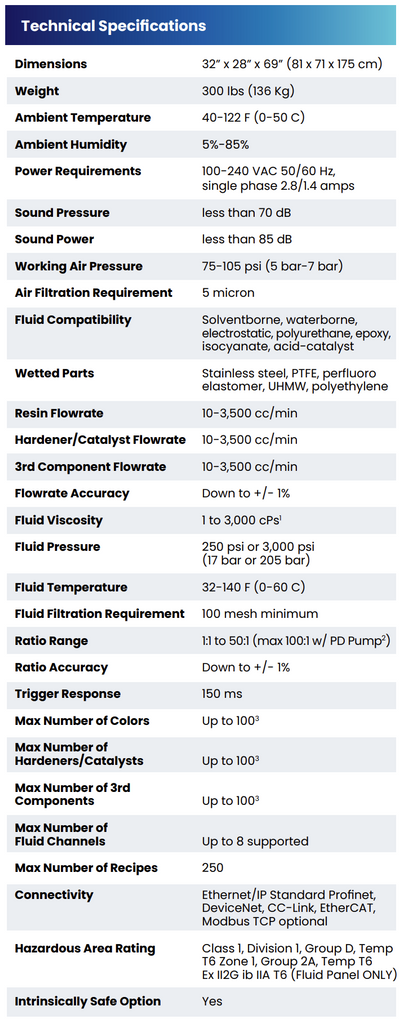

Description: Multi-Component Metering, Mixing, And Flow Control Proportioner for low pressure (250PSI) applications, for automatic or manual spray applications. The IntelliFlow RF2+ is designed to maximize process savings for almost any automatic and manual applicator system, including static, reciprocator, flatline, and robot applications.

• Seamless integration with almost any new or existing process

• Capable of up to 100 colors and catalysts, 1K, 2K and 3K operation

• Modular and scalable design to grow with your process

Best-in-Class Fluid Performance

- Closed-loop flow1 and ratio control ensures the coating is mixed and metered correctly every time

- Proven dynamic mixing reduces paint and solvent waste during color changes

- Standard air-solvent chop2 reduces solvent use by up to 65%

- Critical components are designed for reliability and serviceability

- Fluid panel configurations available to meet a wide range of application needs, including low and medium pressures, solventborne and waterborne coatings, and can be used for with both electrostatic and non-electrostatic applicators.

15" Color Touchscreen

- User-friendly interface

- Primary operation screen streamlines information

- Customization options to suit your process

- Visible alarms include instructional fixes directly on the screen, reducing troubleshooting time

- Automated common processes increase productivity and uptime

Seamless Connectivity and Integration

- Optional communications modules enable direct integration with PLCs, robots, or SCADA systems

- Remote operation via trigger signals for color change, flow rate, and ratio commands

- Cloud-based remote monitoring allows secure operation and diagnosis in real time

- Track and export data for process improvement and VOC reporting

All turn-key configurations include the following:

| • 15” full-color touchscreen with EtherNet/IP communication • Solenoids for up to 12 colors, 4 catalysts • Inlet pressure regulation • Solvent and Air Chop valves on resin stack (low pressure ONLY) |

• Solvent valve on catalyst stack • 2 high-resolution gear flowmeters • 2 closed-loop flow control regulators • Flushable dynamic mix block • Wall mounting hardware |

Floor Stand is for reference only and is purchased separately

Parts and Accessories:

| Part Number | Description |

| 310-2002 | Floor Stand |

| HGB-510-R1-CO | HGB Inlet Pressure Regulator |

| CCV-51XX-XXX | Low Pressure Color Change Stack |

| 240-5202 | Solvent Flowmeter Kit |

| 240-5204 | In-Booth Solvent Flowmeter Kit |

| 310-8020 | In-Booth Fluid Panel Kit 2 Channel Std |

| 310-8021 | In-Booth Fluid Panel Kit 3 Channel Std |

| 310-8022 | In-Booth Fluid Panel Kit 2 Channel Fiberoptic |

| 310-8023 | In-Booth Fluid Panel Kit 3 Channel Fiberoptic |

| 310-8030 | Screen Protector Kit |

| 240-5203 | Remote Color Change Kit 7 Recipe |

| 310-5203 | Remote Color Change Kit 14 Recipe |

| 310-3905-SS | Air Cutoff Kit, 2 Guns |

| HGB-609-9-R38 | Manual Regulator, LP |

| 84-420 | Manual Regulator, HP |

| 240-5205-1 | Gun Flush Box Kit, 1 Gun |

| 240-5205-2 | Gun Flush Box Kit, 2 Gun |

| 310-4143 | Gateway, Profinet |

| 310-4144 | Gateway, DeviceNet |

| 310-4145 | Gateway, CC-Link |

| 310-4146 | Gateway, EtherCAT |

| 310-4164 | Gateway, Modbus TCP |

You will be contacted with a freight quote for shipping. Forklift may be required at delivery

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.