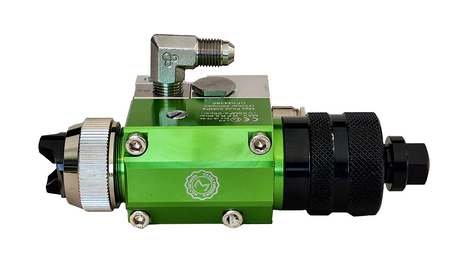

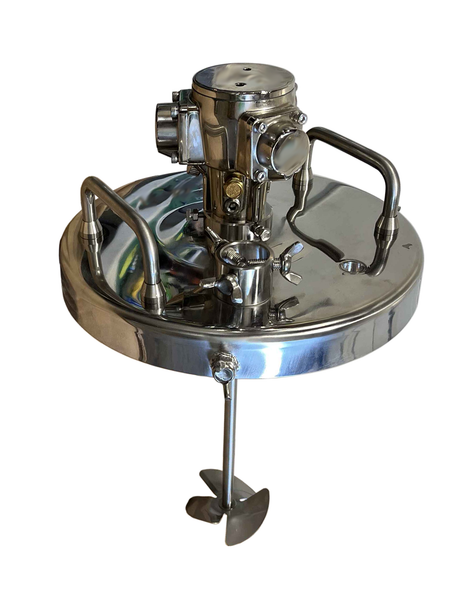

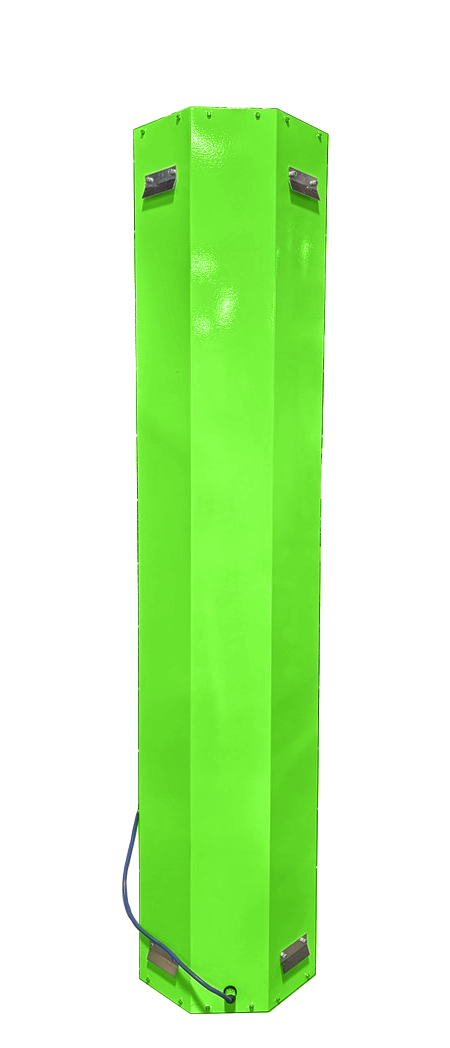

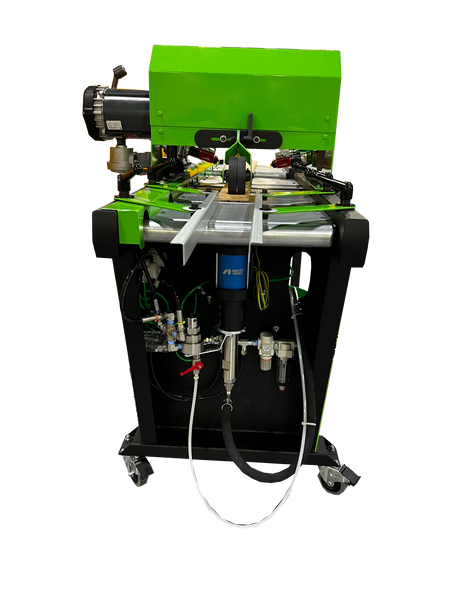

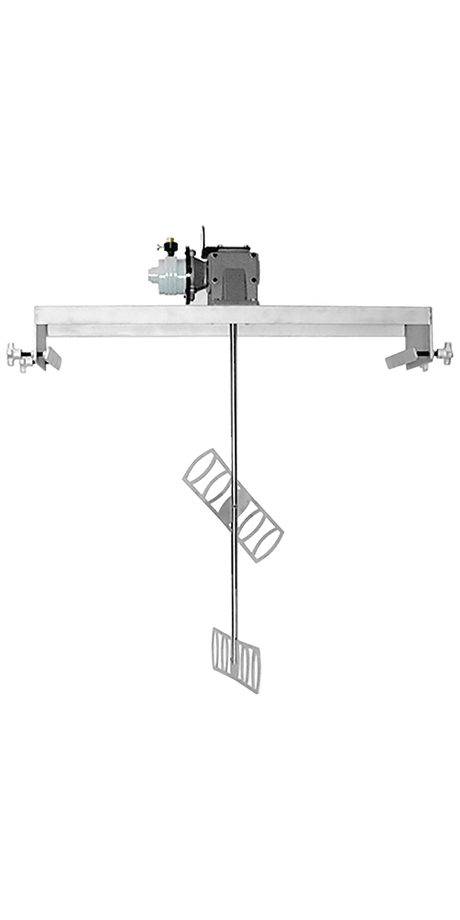

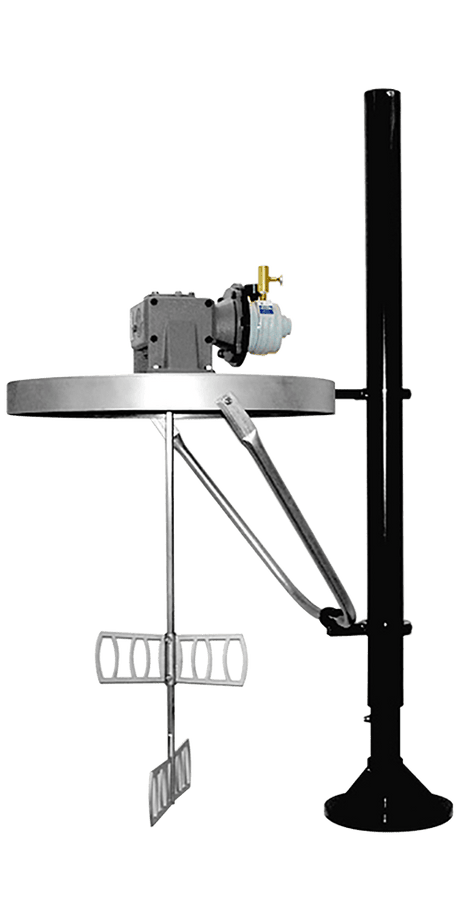

Bomba inteligente Binks E2-30

Bomba inteligente Binks E2-30

Fabricante: Carlisle Binks

Número de pieza: 107074-21

Modelo: E2-30

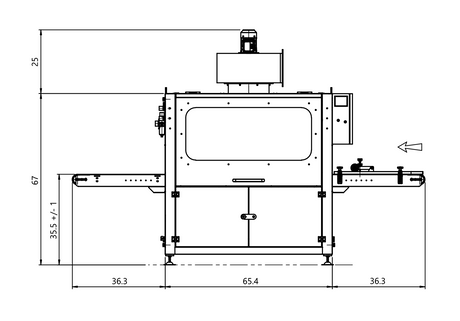

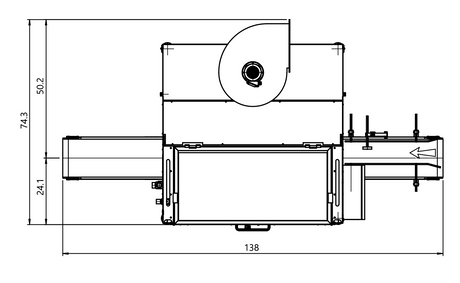

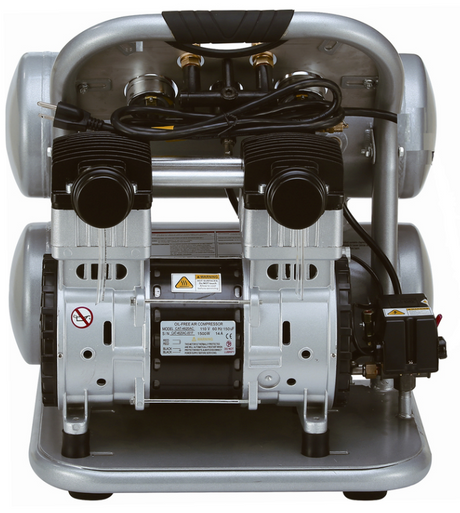

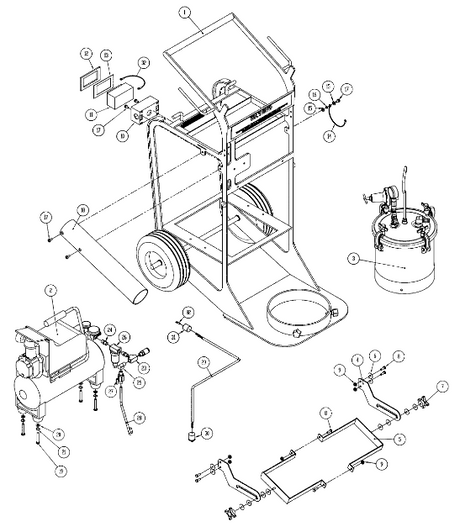

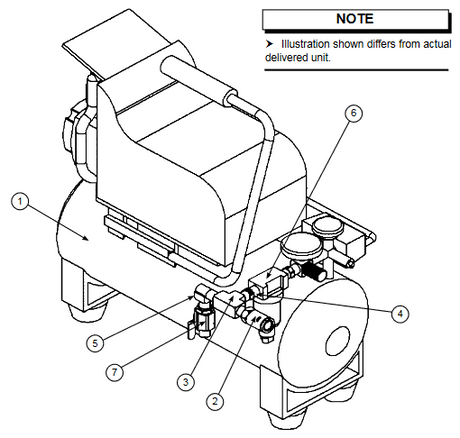

Descripción: Bomba de circulación de control digital avanzado , 300 psi, 8 galones de salida de fluido a 40 ciclos/min.

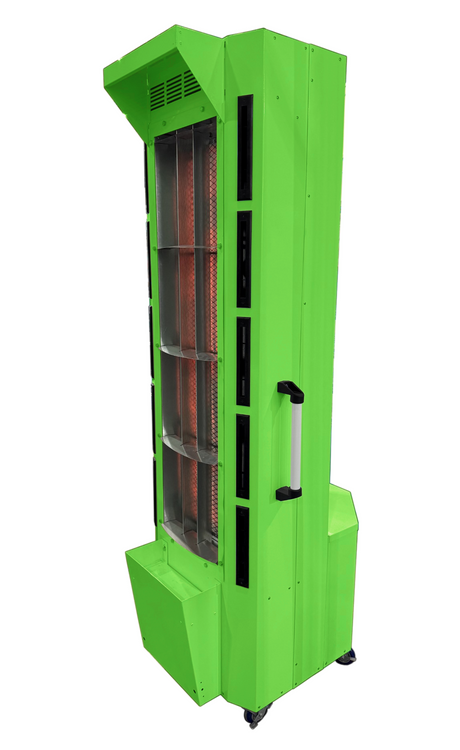

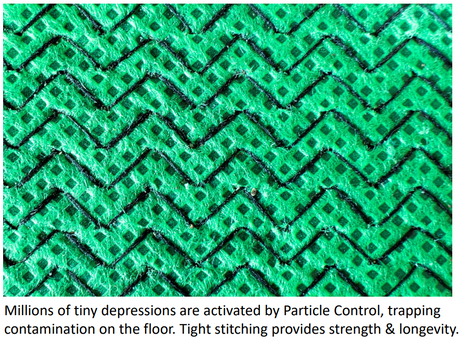

Las bombas inteligentes Binks son famosas por su suministro de material suave y de bajo pulso y por su capacidad de ahorro de energía. Por eso se encuentran en los talleres de pintura de primer nivel y de fabricantes de equipos originales de automóviles más importantes del mundo.

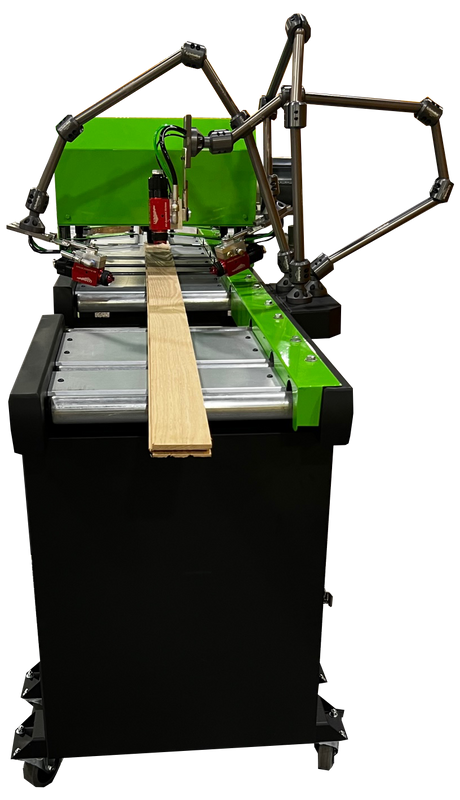

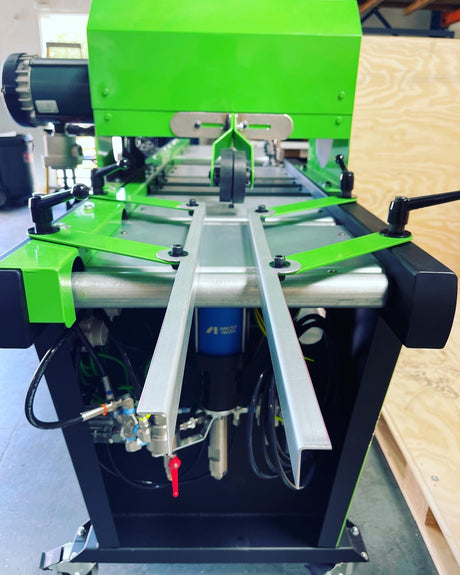

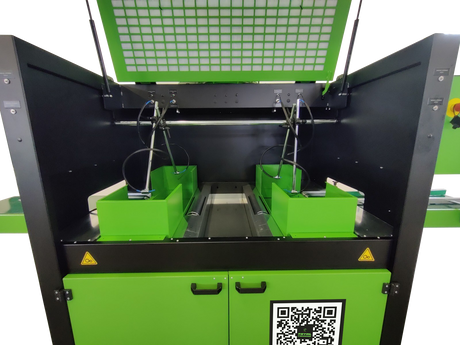

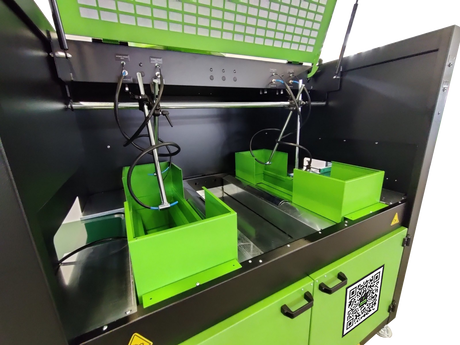

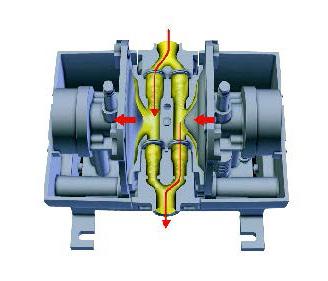

El mecanismo de accionamiento alternativo tiene como núcleo una leva asimétrica de velocidad constante. El perfil de la leva hace que ambos pistones actúen juntos durante un breve período en el cambio, logrando así un flujo continuo y uniforme con fluctuaciones de presión insignificantes. La configuración horizontal de la sección de fluido proporciona un empuje igual en cada carrera, lo que logra un flujo constante y controlable. Todos estos elementos se combinan para proporcionar un flujo uniforme de material, eliminando la necesidad de una cámara de compensación.

El sistema inteligente Binks garantiza que el material se entregue en el punto de aplicación solo cuando es necesario, lo que reduce drásticamente el consumo de energía y pintura. El sistema inteligente Binks monitorea cuándo la cabina de pintura está en funcionamiento de circuito cerrado y aumenta la presión y el flujo de material para satisfacer la demanda. Al volver al circuito abierto, el sistema inteligente Binks disminuye automáticamente la velocidad de la bomba para mantener los requisitos mínimos de presión y flujo. El controlador de tarjeta inteligente interactúa sin problemas con todos los principales software de control de PLC. Utilizando salidas Modbus, puede conectarse con PLC de Siemens, Alan Bradley y Mitsubishi.

Características:

- Ahorro significativo de energía : el accionamiento eléctrico combinado con el control inteligente proporciona un ahorro significativo de energía y costos en comparación con las bombas neumáticas.

- Accionamiento alternativo patentado : incorpora un mecanismo de carro deslizante con leva asimétrica de velocidad constante, lo que proporciona una transición suave y prácticamente elimina las fluctuaciones de presión del material. No requiere cámara de compensación.

- Control de caudal mediante inversor de frecuencia CA. Controlable de forma continua en un rango de 10 a 40 ciclos por minuto.

- Los sellos de pistón de larga duración están lubricados con pintura en ambos lados, lo que aumenta la vida útil del sello y garantiza que no haya fugas externas al final de la vida útil del sello.

- Los asientos de bolas de carburo de tungsteno y los pistones revestidos de cerámica garantizan una larga vida útil, incluso al bombear materiales agresivos y abrasivos.

- Los sellos de fuelle de eje de PTFE cerrados eliminan la necesidad de lubricar la empaquetadura del eje. Es vital cuando se bombean materiales sensibles a la luz (UV) y la humedad (catalizador).

- Elección del modo operativo : modo de flujo simple o modo automático de 'Control de presión' para lograr el máximo ahorro de energía 'inteligente'.

- Conexiones de fluidos : Las conexiones de entrada y salida sanitarias garantizan que no haya bolsas que puedan atrapar pintura en las uniones de válvulas y colectores.

| Materiales adecuados | Aplicaciones típicas |

|

|

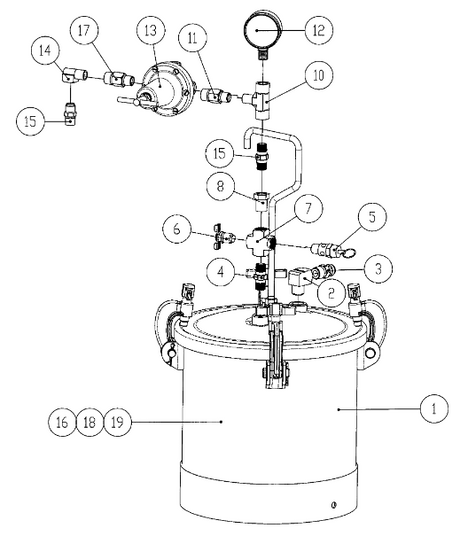

Accesorios:

- ( 192800 ) - Tarjeta inteligente

- ( 10775X ) - Regulador de contrapresión

- ( 1041XX ) - Válvula de alivio de presión

- ( 192547 ) - Transductor de presión

- ( 502144 ) - Gama de presostatos

- ( 192720 ) - Colector de sensores

- ( 502501 ) - Caja de control BPR

- ( 192008 ) - Junta sanitaria

- ( 192009 ) - Abrazadera sanitaria

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.