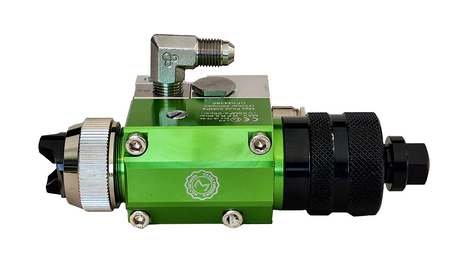

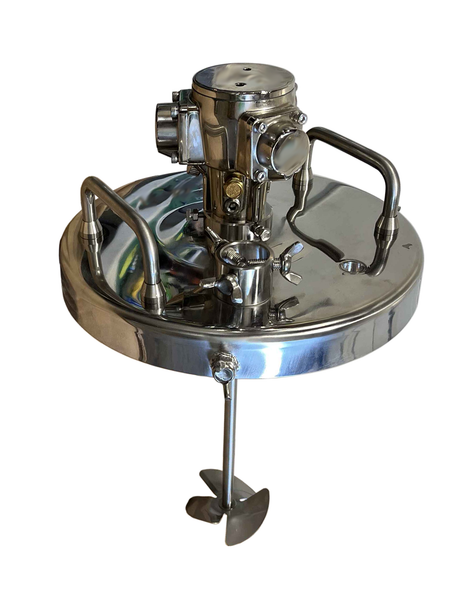

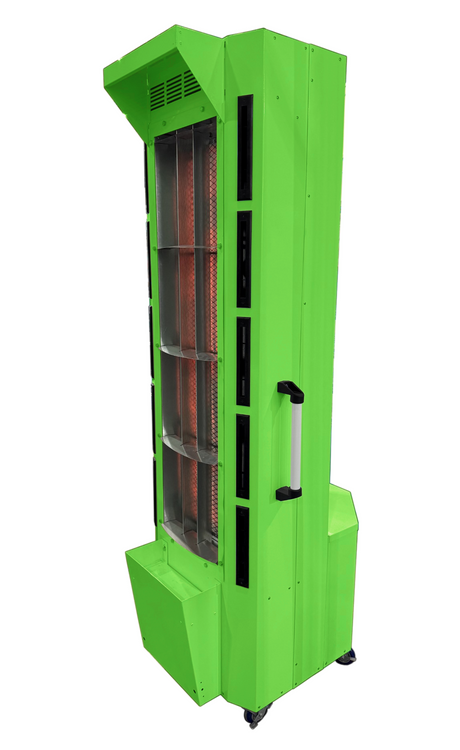

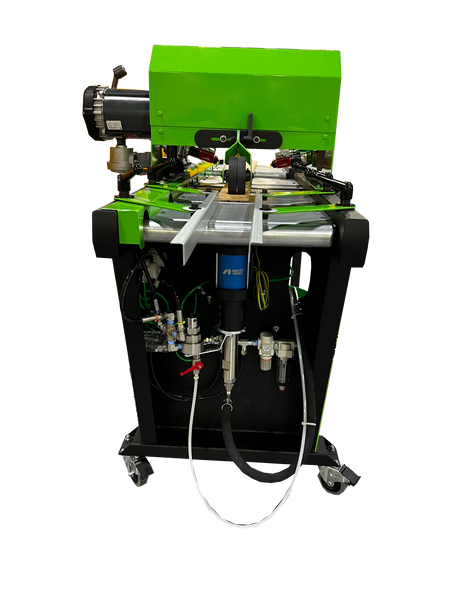

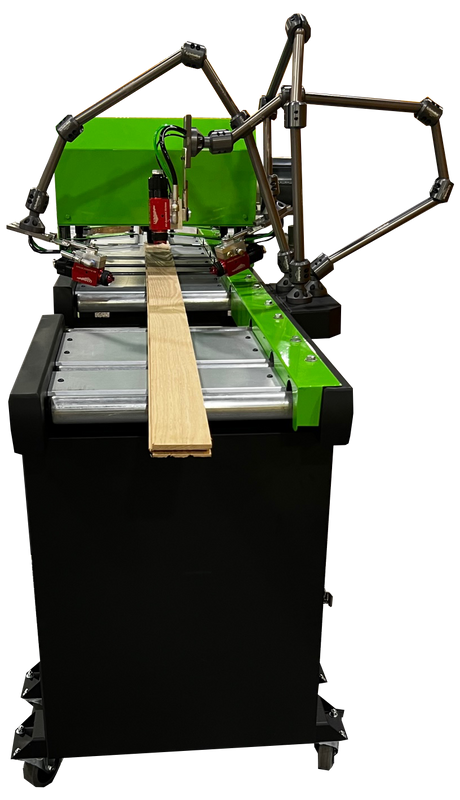

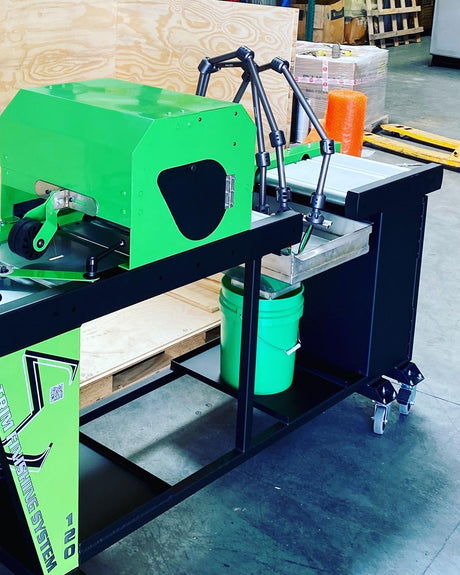

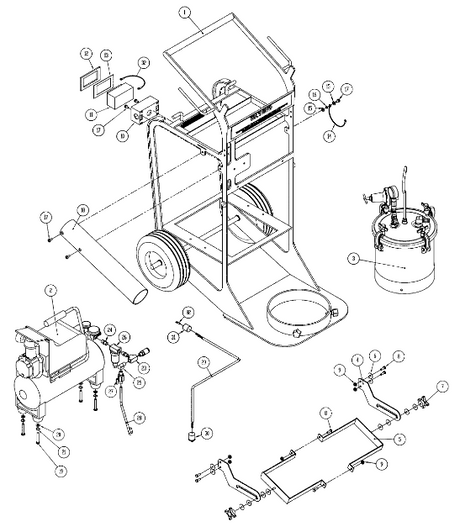

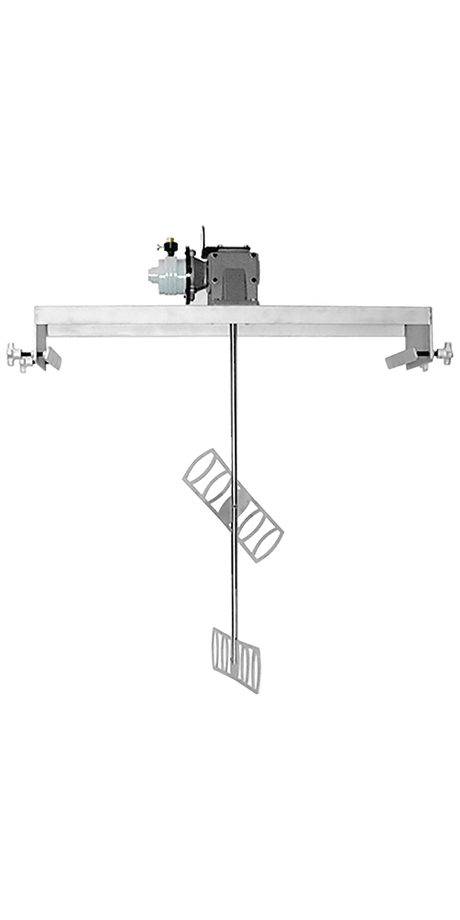

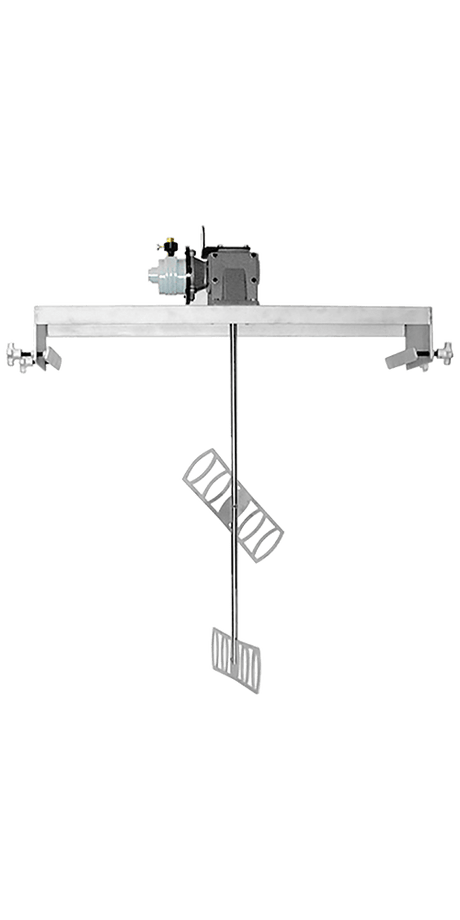

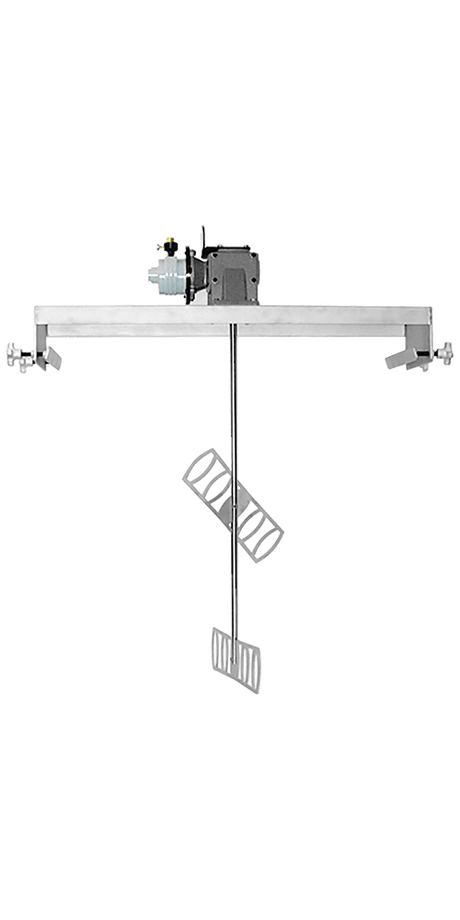

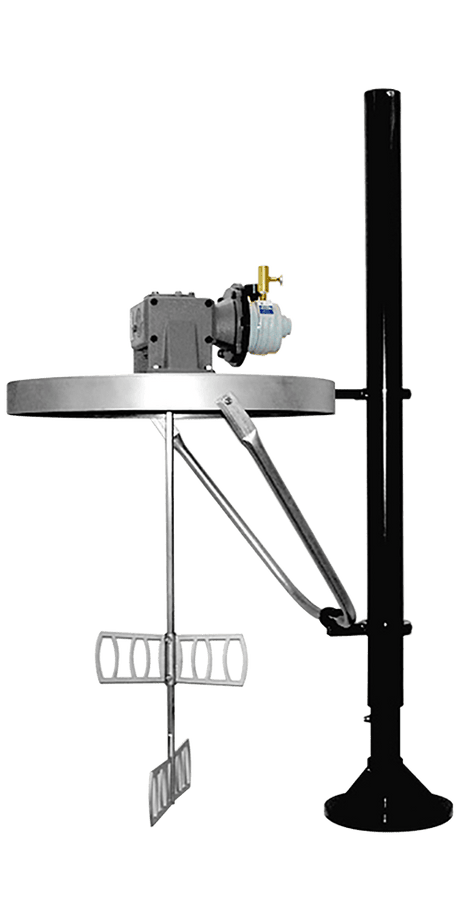

Dosificador automático Ransburg IntelliFlow RF2 de 2K y baja presión

Ransburg IntelliFlow es la próxima generación de dosificación intuitiva, precisa y conectada.

Fabricante: Ransburg

Número de pieza: RF2-LA2-XX-XX-X

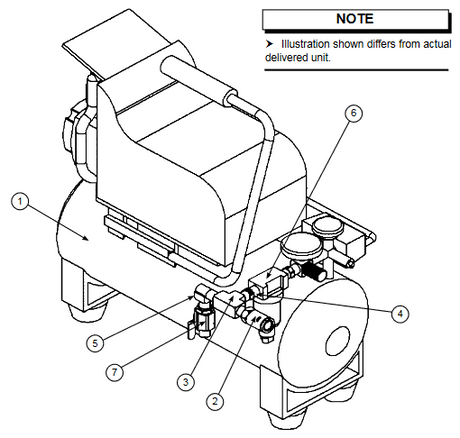

Descripción: Baja presión, 300 psi (20 bar), aplicación automática

Dosificador de dos componentes (2K) para control de flujo, mezcla y medición. Para aplicaciones que requieran 3K, comuníquese con nosotros al (844) 898-1082 para solicitar una cotización.

La familia de productos IntelliFlow de Ransburg ofrece automatización avanzada y facilidad de uso para impulsar la eficiencia, el tiempo de funcionamiento y la optimización de su proceso. Las pantallas táctiles grandes y a todo color con procesos automatizados reducen significativamente el tiempo de capacitación y garantizan que se eviten los errores del operador. La conectividad basada en la nube permite monitorear y solucionar problemas del equipo en tiempo real desde cualquier parte del mundo. Y los componentes de fluidos flexibles y de alto rendimiento brindan una relación superior y una precisión de flujo a la vez que maximizan el ahorro de residuos de solventes y recubrimientos.

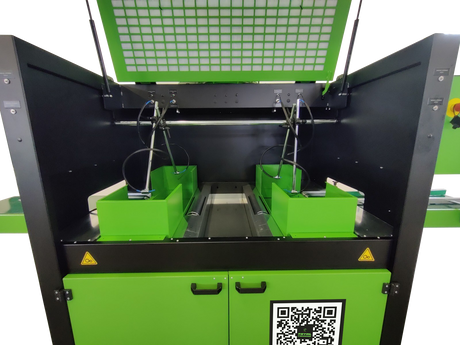

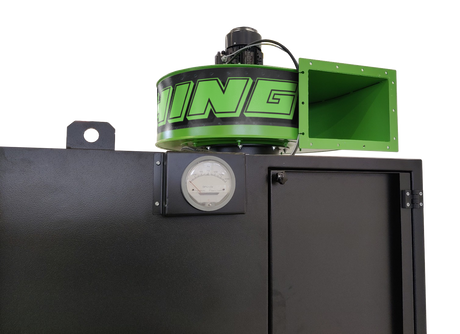

Pantalla táctil intuitiva de 15″ a todo color

- La interfaz fácil de aprender resultará natural tanto para los operadores nuevos como para los experimentados.

- Las pantallas de operación primaria optimizadas muestran solo la información que necesita saber, junto con un conjunto completo de opciones de personalización para adaptar el equipo a su proceso.

- Automatice procesos comunes y evite errores costosos para aumentar la productividad y el tiempo de actividad.

- Las alarmas visibles le indican cuál es el error y exactamente cómo solucionarlo, lo que reduce el tiempo de resolución de problemas.

Conectividad e integración perfectas

- La comunicación EtherNet/IP viene de serie para una integración perfecta con su PLC, robot o sistema SCADA, con muchos otros protocolos también disponibles.

- La unidad se puede operar de forma completamente remota enviando señales de activación, cambio de color, caudal y comandos de relación.

- La monitorización remota basada en la nube permite operar o diagnosticar el equipo de forma segura en tiempo real desde cualquier lugar del mundo.

- Realice un seguimiento y exporte datos de procesos organizados en tiempo real o por lotes para mejorar los procesos y generar informes de VOC

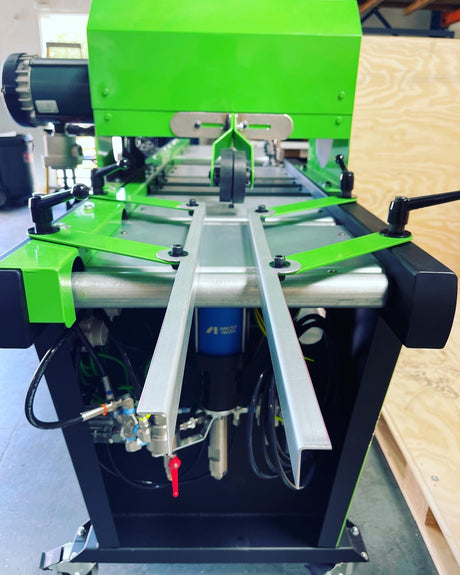

El mejor rendimiento de fluidos de su clase

- El verdadero control de flujo y relación de circuito cerrado brinda una precisión inigualable, lo que garantiza que el recubrimiento se mezcle y dosifique correctamente en todo momento.

- La mezcla dinámica comprobada reduce el desperdicio de pintura y solvente durante cada cambio de color, lo que genera ahorros significativos para su negocio.

- El corte estándar de aire y disolvente reduce el uso de disolvente hasta en un 65 %

- Los componentes críticos están diseñados teniendo en cuenta la confiabilidad y la facilidad de servicio, lo que aumenta el tiempo de actividad y minimiza el tiempo de inactividad inesperado.

Soluciones flexibles y escalables para mejorar cualquier proceso

- Configuraciones de fluidos flexibles disponibles para satisfacer las necesidades de todos los recubrimientos principales, a base de solventes, a base de agua, electrostáticos o no electrostáticos de baja y alta presión.

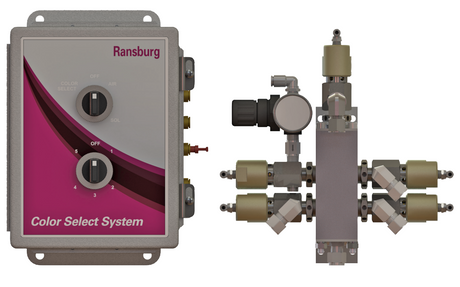

- Hasta 100 colores + endurecedores + 3K con cambios, descargas y recetas programables.

- Amplia gama de accesorios disponibles para adaptar el equipo a su proceso exacto.

- El diseño modular permite que el equipo crezca con su negocio: agregue fácilmente colores, catalizadores y circuitos de fluidos adicionales a medida que su proceso se expande.

Cuándo elegir unidades RF2 automáticas o manuales:

- Los beneficios del RF2 automático incluyen control de caudal o regulación de presión de fluido pilotada por aire y el mayor nivel de precisión de relación en una amplia gama de caudales.

- Algunas de las adiciones al RF2 automático incluyen reguladores de presión de fluido en las pilas de válvulas y un MVR (regulador de válvula de material) para los componentes A, B, C.

- El RF2 automático se puede utilizar en modo automático o manual para quienes realizan aplicaciones de pulverización manuales y están considerando actualizar a automático en el futuro.

Cómo seleccionar su configuración llave en mano:

- Seleccione la cantidad de colores y catalizadores. Si la cantidad de colores y catalizadores que desea no aparece en la lista, solicite una configuración de 1 color y 1 catalizador y solicite las pilas de colores por separado.

- Seleccione la compatibilidad del material (estándar o isocianato).

- Seleccione entre piezas y accesorios adicionales que se enumeran a continuación.

Todas las configuraciones incluyen lo siguiente:

- Pantalla táctil a todo color de 15” con comunicación EtherNet/IP

- Solenoides para hasta 12 colores, 4 catalizadores

- Regulación de presión de entrada

- Válvulas de corte de aire y solvente en la pila de color (excepto configuraciones de 1 color)

- Válvulas de disolvente en la pila de catalizador (excepto configuraciones de 1 catalizador)

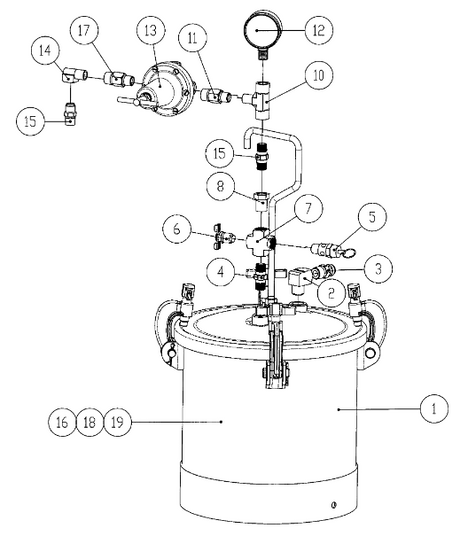

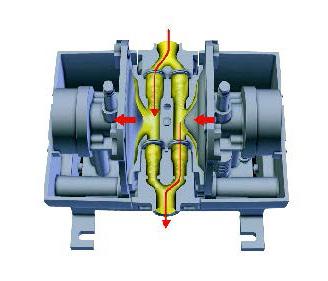

- 2 caudalímetros de engranajes de alta resolución

- 2 reguladores de control de flujo de circuito cerrado

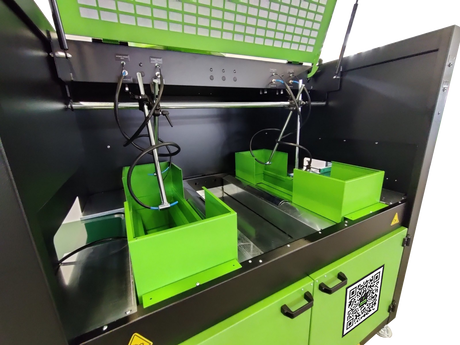

- Bloque de mezcla dinámica desechable

- Herrajes para montaje en pared

Piezas y accesorios:

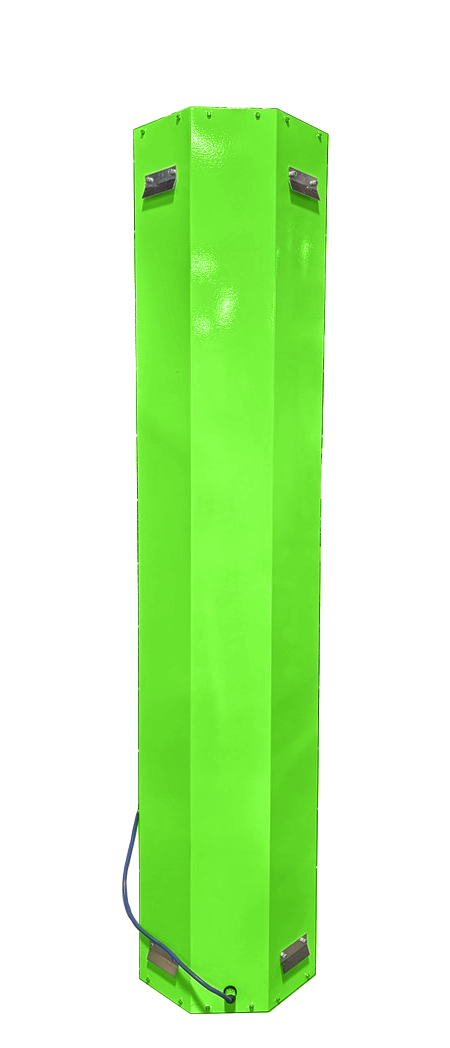

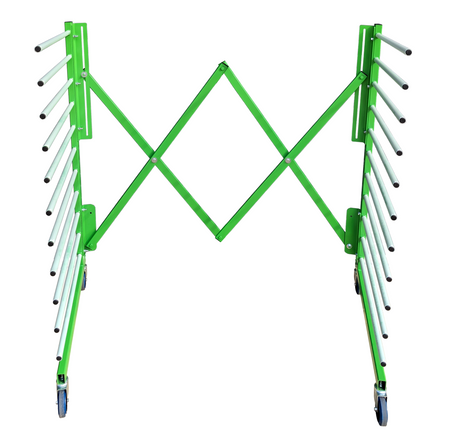

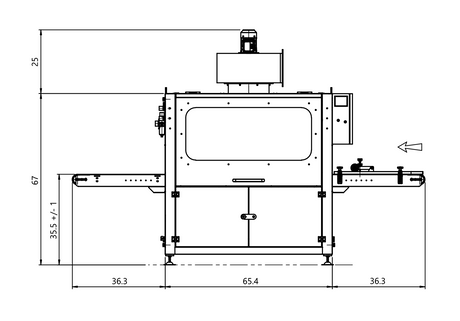

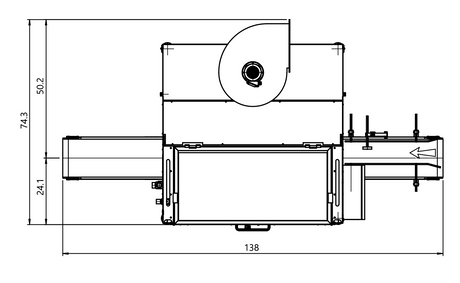

- (310-2002) Kit de soporte de suelo, RF2

- (HGB-510-R1-CO) Regulador de presión de entrada HGB

- (CCV-51XX-XXX) Pila de cambio de color de baja presión

-

(CCV-503-SS) Válvula CCV de baja presión

- (54-9XX) Filtro en línea de baja presión

- (240-5203) Kit de cambio de color remoto

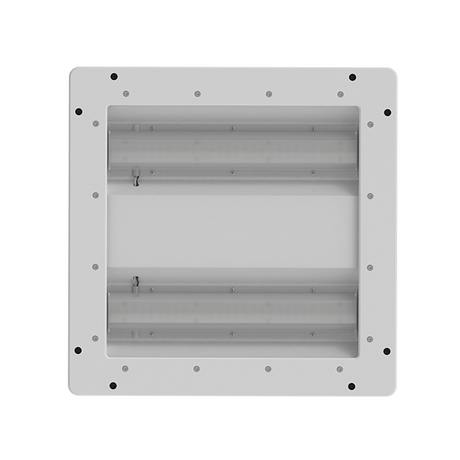

- (310-8020) Kit de panel de fluidos para cabina - 2 canales estándar

- (310-8021) Kit de panel de fluidos para cabina - 3 canales estándar

- (310-8022) Kit de panel de fluidos para cabina: fibra óptica de 2 canales

- (310-8023) Kit de panel de fluidos para cabina - Fibra óptica de 3 canales

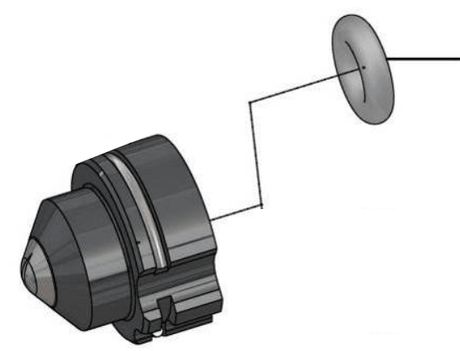

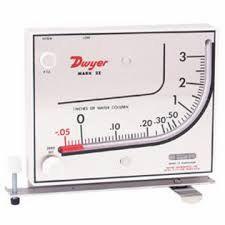

- (310-900X) Caudalímetro de engranajes

- (310-8030) Kit de protección de pantalla

- (310-3905-SS) Kit de corte de aire, 2 pistolas

- (310-4170) Módulo Wi-Fi

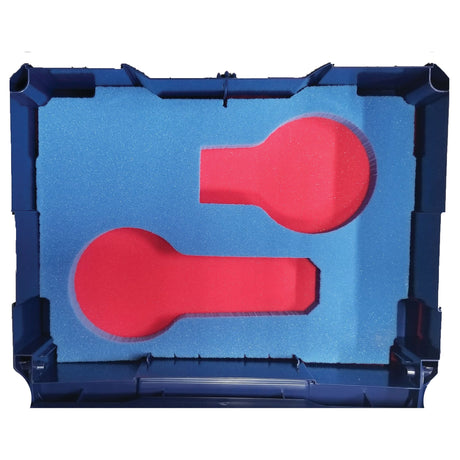

- (240-5205-X) Kit de caja de descarga de armas, 1 o 2 pistolas

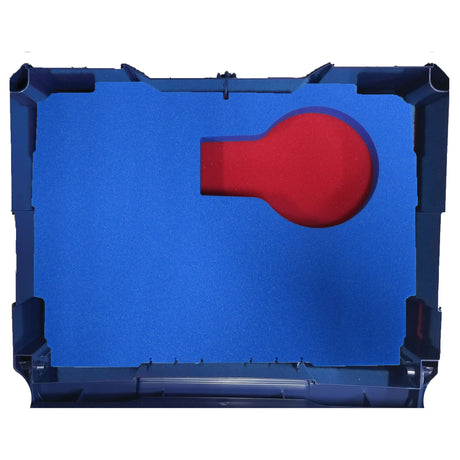

- (240-3198-X) Monturas de caja empotradas - Varios modelos de armas

- (310-4142) Puerta de enlace de comunicaciones, EtherNet IP

- (310-4143) Puerta de enlace de comunicaciones, Profinet

- (310-4144) Puerta de enlace de comunicaciones, DeviceNet

- (310-4145) Puerta de enlace de comunicaciones, CC-Link

- (310-4146) Puerta de enlace de comunicaciones, EtherCAT

Literatura:

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.