ARO

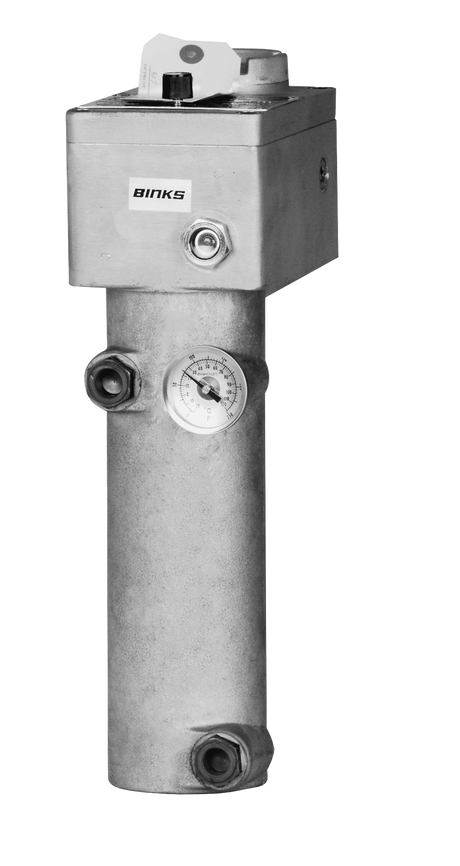

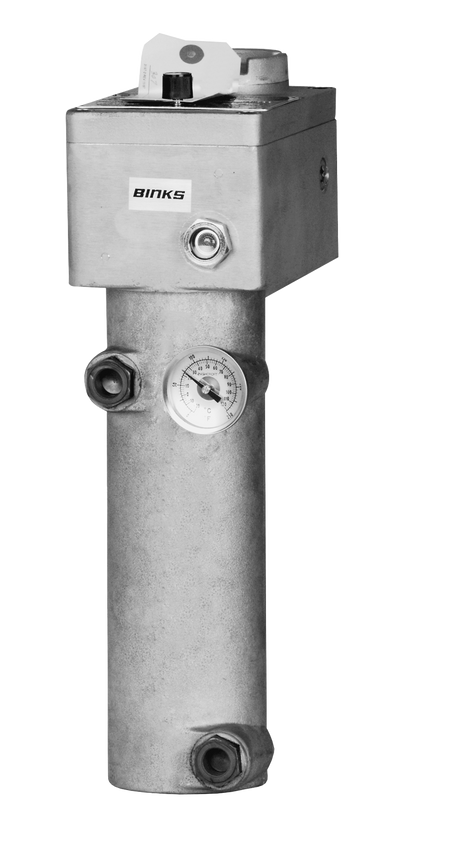

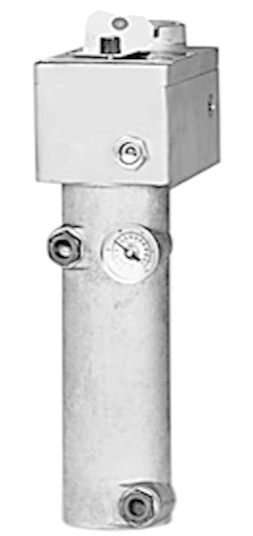

ARO Inline Paint Fluid Heater Stainless Steel - Heater Only

Regular priceUnit price /Unavailable

Gaze upon our Photo Gallery Click Here

Explore products in our Catalog Click Here

Expand your knowledge in our Literature Library Click Here

Total Finishing Supplies

Total Finishing Blue Painter's Tape

Total Finishing Supplies

Total Finishing Green Masking Tape

Total Finishing Supplies

Total Finishing Low Tack Cabinetry Protective Paper Tape

Total Finishing Supplies UltraSonic

1.5 Gallon Heated Stainless Steel, Ultra Sonic Cleaner Tank

Total Finishing Supplies UltraSonic

TF-Sonic 33 - Ultra Sonic Cleaning Fluid for Paint Spray Gun and Powder Coat Removal

Total Finishing Supplies

TFS Total Power Brush™ Painter's Backpack

Titan

Titan Impact X 120 18V Ultimate Mobile Spray System

Total Finishing Supplies

AUTO VIPER-X® Air Assisted Airless (AAA) Automatic Spray Gun

Total Finishing Supplies

Total Finishing 5 Gallon Agitator With Stainless Steel Lid

Total Finishing Supplies

VIPER® Mix-Tech Air Assisted Airless Spray Gun

Total Finishing Supplies Kremlin K Parts

TFS Spray Tip Cleaning Needles - 12 Needles for tips (non-OEM)

Total Finishing Supplies Kremlin K Parts

Aftermarket KREMLIN® 129.609.901 Tip Accessories / Micro Tip Filter (pack of 10 filters) (Non-OEM)

Total Finishing Supplies Kremlin K Parts

Aftermarket KREMLIN® 129.529.903 Compatible O-Ring Teflon Tip Seal (Non-OEM)

Total Finishing Supplies Kremlin K Parts

Aftermarket KREMLIN® Air Assisted Airless Tip (Non-OEM)

Total Finishing Supplies Kremlin K Parts

Aftermarket KREMLIN® Air-Assisted Airless Tip—Ultra Series Fine Finish Tip (Non-OEM)

Total Finishing Supplies

Tip Spa™ Tip Cleaner By Total Finishing

Total Finishing Supplies

Total Finishing Tip Spa™ - Spray

Total Finishing Supplies Kremlin K Parts

SurfPrep

SurfPrep 3" x 4" Electric Ray ProFoam Sanding System Kit

SurfPrep

Surfprep 3" x 4" Storm Air ProFoam Sanding System Kits

Total Finishing Supplies Racks

TOTALrack™ for Drying | Cabinet Door & Paint Drying Rack | Made in USA

Total Finishing Supplies Racks

Total Finishing Supplies Racks

Total Finishing Supplies Racks

Total Finishing Supplies Racks

Anest Iwata

Anest Iwata Premium Micro-Fabric Spray Suit

Total Finishing Solutions

Trim Finishing System 120 Linear Spray Machine

Total Finishing Solutions

C.A. Technologies

2.5 Gallon Stainless Steel Pressure Tank

Anest Iwata

Anest Iwata PC-18D Pressure Pot, 2 L Capacity

Total Finishing Supplies

TFS CYCLOPS™ Low Pressure Diaphragm Pump

Anest Iwata

Anest Iwata WS-200 SP Pressure Feed Spray Gun

Carlisle Binks

Binks DVX Pressure Feed Manual Spray Gun

Carlisle Binks

Binks DVX Gravity Feed Manual Spray Gun

3M

3M™ Versaflo™ Powered Air Purifying Respirator Painters Kit TR-800-PSK/94248(AAD)

Total Finishing Supplies

High-Pressure Fluid Regulator (SS)

Total Finishing Supplies

MAMBA® Mix-Tech Air Assisted Airless Manual Spray Gun with Reversible Tip

TriTech

TriTech T93R Reversible Ultra-Finish Professional Tip

Total Finishing Supplies Hoses

TFS 1/4” Female, 3/16" High Pressure Hose Set, 25’

Total Finishing Supplies Hoses

TFS 1/4” Female, 3/16" High Pressure Hose Set, 50'

Becca

Becca Standard High Capacity Solvent Saver (6 Gallon) Recycler

Buffalo Industries

Buffalo Industries XL Waterproof Shoe and Boot Covers

Buffalo Industries

Buffalo Industries Ultimate Fine Finish Wipers Cloth Rags

Buffalo Industries

Buffalo Industries Cotton Tack Cloths

Buffalo Industries

Buffalo Industries 6.5 Gallon Bucket Spill Kits

Total Finishing Supplies

Any Airless to AAA Upgrade Kit with VIPER® Gun

Total Finishing Supplies

Any Airless to AAA Upgrade Kit with MAMBA® Gun

California Air Tools

California Air Tools 2.0 HP, 4.6 Gal. Ultra Quiet Air Compressor

Dedoes

Dedoes Thrift-O-Matic Sixteen Place Gallon Mixing Machine

Carlisle DeVilbiss

DeVilbiss DAD500 3-Stage Desiccant Dryer Unit

Carlisle DeVilbiss

DeVilbiss EXL Pressure Feed Spray Gun

Fillon Technologies

Fill-One+ Aerosol Filling Machine w/ Demo Plate

Fillon Technologies

Sartorius PMA.Power 5-Gallon Digital Scale

Fillon Technologies

Sartorius PMA.Evolution Digital scale

HERO

Hero Vortex Mixer One Gallon Counter Top Models

LDPI

LDPI Industrial Lighting Series LE484 Class I Divison 2 LED Fixture

Total Finishing Supplies Spray Booth Filters

Total Finishing Supplies Spray Booth Filters

Total Finishing Supplies Spray Booth Filters

Total Finishing Supplies Spray Booth Filters

Carlisle Ransburg

Ransburg Number #2 Deuce Cart Electrostatic Finishing System

Carlisle Ransburg

RansFlex AA85 Electrostatic Applicator

Carlisle Ransburg

Carlisle Ransburg

Ransburg Meter Kit - Paint Test Probe

Total Finishing Supplies

Total Finishing Supplies Downdraft Table 6' x 3'

SurfPrep

SurfPrep Professional Onsite 8 Gallon Vacuum

Total Finishing Supplies Agitators

Total Finishing Supplies Agitators

Heavy Duty Back Geared Mixer Unit w/Elevator

Total Finishing Supplies Kremlin K Parts

High Pressure Y-Block - 1/4" NPS (M) x 1/4" NPSM (F)

Total Finishing Supplies Spray Booth Filters

Paint Spray Booth Light Protective Film

Total Finishing Supplies Spray Booth Filters

Total Finishing Supplies Spray Booth Filters

Wagner

Wagner Cobra 40-10 High Pressure Diaphragm Pump 5L Hopper Spray Pack

Wagner

Wagner TopFinish DD10 Double Diaphragm Pumps

Walcom

Walcom Thermodry TD1 Pro Unit (IPH Hose Included)

Total Finishing Supplies

VIPER® Mix-Tech Air Assisted Airless Spray Gun

Total Finishing Supplies

MAMBA® Mix-Tech Air Assisted Airless Manual Spray Gun with Reversible Tip

Total Finishing Supplies

AUTO VIPER-X® Air Assisted Airless (AAA) Automatic Spray Gun

Total Finishing Supplies Racks

TOTALrack™ for Drying | Cabinet Door & Paint Drying Rack | Made in USA

Total Finishing Supplies

Any Airless to AAA Upgrade Kit with VIPER® Gun

Total Finishing Supplies

Any Airless to AAA Upgrade Kit with MAMBA® Gun

SurfPrep

CLOSE OUT - SurfPrep Rectangle Sander Foam Pads

SurfPrep

CLOSE OUT - SurfPrep Detail (Triangle) Sanding Foam Pads

SurfPrep

SurfPrep 3" Foam Discs - 5mm Thick (Premium Red A/O)

SurfPrep

SurfPrep 5" Foam Discs - 5mm Thick (Premium Red A/O) - 25 Pads/Box - Close Out

C.A. Technologies

CAT-X Black Teflon™ Gravity Spray Gun W/ Pressurized 3M PPS 2.0 Cup System 850ml

Over 30,000 items online and growing

Free help & advice from our product experts

Shop by application, brand, or process

Order 24 hours a day, 7 days a week

EXPERTS STANDING BY TO HELP!

Inline Fluid Heater - A Way to Control Viscosity

Temperature control is a critical aspect of high-quality finishing. Temperature influences how easily the paint pumps, atomizes, and flows out. It affects how quickly the coating dries (or cures) and how hard the film becomes. Often the exact temperature at which something in the paint shop happens is less important than the consistency of the temperature. Let’s dig in with our FAQs.

What temperatures are important?

At least six temperatures are important enough to monitor:

Principle

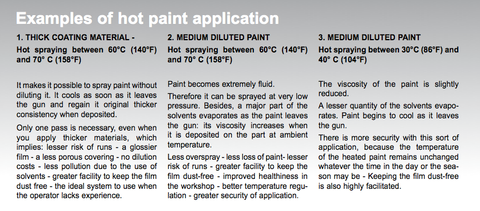

By raising the temperature of a fluid, you reduce its viscosity: for instance, heating paint up to 60° or 80° C will have the same result as using a solvent.

Hot paint spraying is also a good solution to maintain paints at a regular temperature, preserving them from the variations of temperature in a workshop all and every day.

Apply more paint per pass

As the discharged paint exits the gun, two factors raise the viscosity of the paint. The accelerated evaporation of the hot solvents and the cooling of the resin. The net effect is the ability to apply more paint per pass without runs.

Process

Cold paint is discharged into the heater (4) under the action of pressure. It is instantly warmed to the selected heat and reaches the spray gun (3) after passing through the filter (8) at a similar temperature.

What happens if the paint is too warm or too cold?

Cold paint will be too viscous (too thick). It will pump, atomize and flow out with difficulty. Also, the rate of solvent loss from cold paint on the part will be reduced. The retained solvent will keep the paint runny, and sagging may result. This effect usually overcomes the reduced flow from higher viscosity. The result is more sags on cold mornings. The retained solvent may also lead to popping in the oven.

Warm paint flows too easily. When warm, more paint than is needed will flow at a given pump setting. Atomization will require more air pressure and a larger paint cloud will form. The result will be wasted paint and more mess.

In some cases, paint temperature variation may influence the color.

How closely should the paint temperature be held?

This is not an easy-to-answer question. It depends on the solvent blend (fast or slow) and the skill of the operator. Skillful painters can compensate for considerable variation in temperature, line speed, solvent blend, etc.

A manual application can usually accommodate a plus or minus 5 degrees Fahrenheit temperature variation without much problem. Automatic applicators work best if the paint varies no more than 3 degrees Fahrenheit from the recommended value.

How can I control the paint temperature?

The best option is to use a paint heater.

How do paint heaters work?

There are at least four ways to heat paint before application:

1. Non-circulating (dead-ended) systems use a warm liquid pumped through a special hose inside the paint hose. The circulating warm liquid is heated electrically and it warms the paint.

2. Circulating systems usually use an electrical resistance element in a cast aluminum body through which the paint is pumped. This is the most common approach to heating paint.

3. Sometimes an electric liquid-to-liquid system heat exchanger is used to heat the paint. These systems are somewhat complex, but they can be used to cool as well as heat. That might be a useful feature for catalyzed systems.

4. You can also use an electric drum or pail heater. This heater uses a belt that wraps around the drum. Plugin and set the thermostat to what you want.

Won’t the paint viscosity drop if I heat the paint?

Sure, but so what — at least the viscosity will be consistent. If the viscosity is too low, you can simply spray at higher solids. In fact, some high-solid paints are heated mainly to drop the viscosity into a sprayable range. The paint supplier may want to change the solvent blend to accommodate a higher spray temperature.

What’s the problem if the parts are too warm or too cold?

Cold parts present two problems. The first is that they cool the paint, with the result being that the paint may sag in the booth or pop in the oven (due to retained solvent). Second, if the parts are cool enough, they may condense water vapor from the air and coat the surface with a film of water prior to painting. The water film reduces adhesion and may cause the paint to slide off the surface.

Warm parts may dry the paint droplets as they strike the surface and prevent good leveling with waterborne warm parts may reduce the paint viscosity and lead to sags.

How much hotter or colder than the paint can the parts be?

That’s not an easy question to answer. It depends on the solvent blend in the paint and the humidity of the air. Five or 10 degrees Fahrenheit is usually not a problem.

Viscosity Controls - Site Navigation

Shop by Brand

|

|

Carlisle Binks

Binks Fluid Heater - Heater Only

ARO

ARO Inline Paint Fluid Heater Stainless Steel - Package

ARO

ARO Inline Paint Fluid Heater Stainless Steel - Heater Only

Visit our support center

Expert help & advice

Check your order status

Updates & tracking

Returns & exchanges

All you need to know

| Item | Price | Qty | Total | |

|---|---|---|---|---|

| Subtotal |

$0.00 |

|||

| Shipping | ||||

| Total | ||||