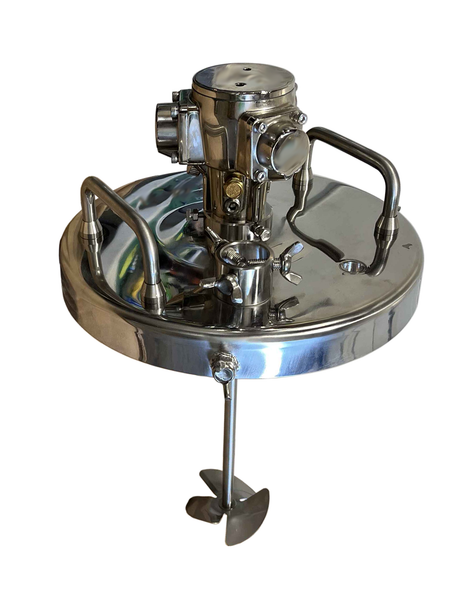

Pirate Brand E-Series Blast Pots

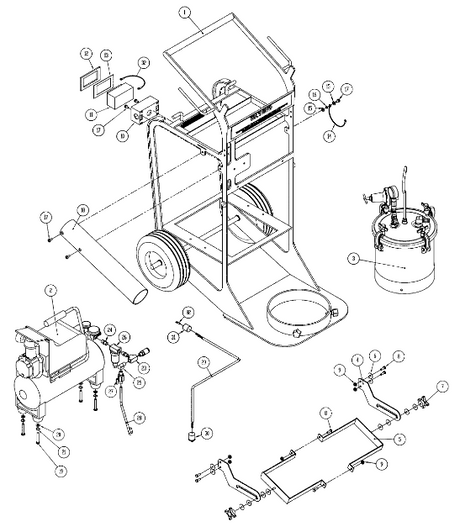

Browse our inventory of Pirate Brand blast pots used for abrasive blasting. Pirate Brand Abrasive Blasting provides high quality sandblasting equipment and parts that are used to remove surface coatings, clean rust and grease, and prepare surfaces for paint and coatings.

Our experts are standing by to help you select the right product for your application. With more than 30 years of industry experience Total Finishing SUPPLIES has the right expertise. Please call or text us at 503-545-3176 with any questions. We're on standby to help!

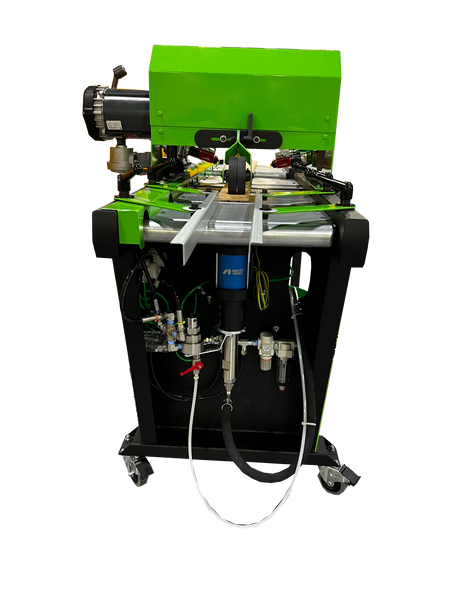

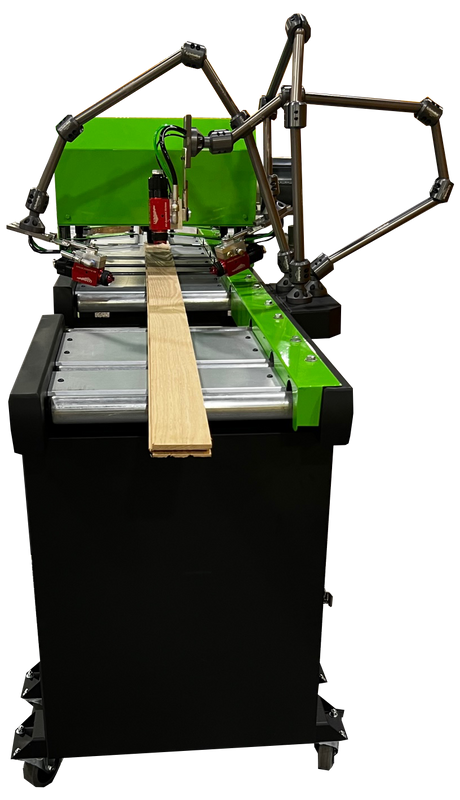

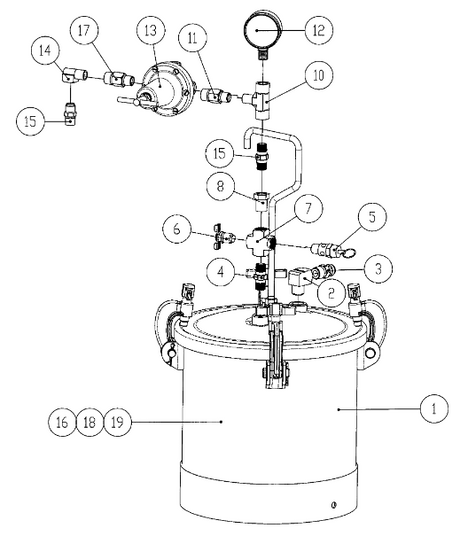

Features

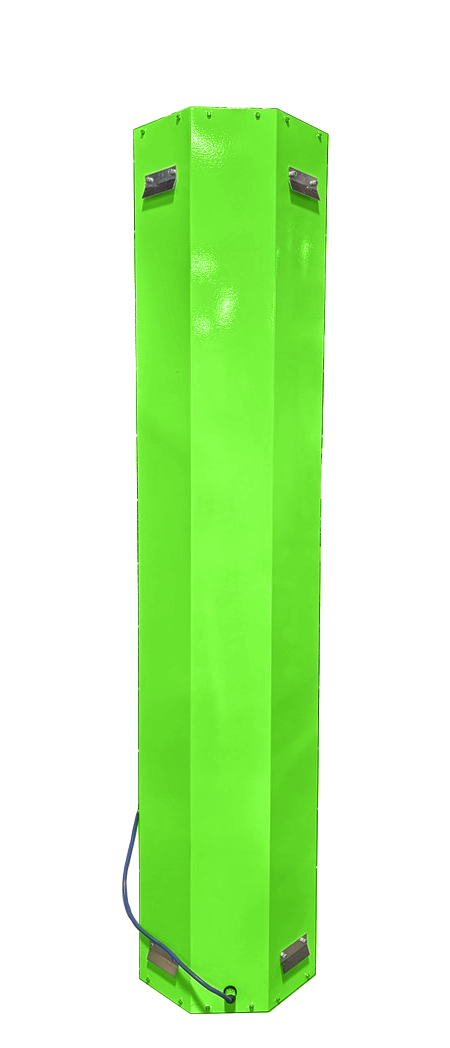

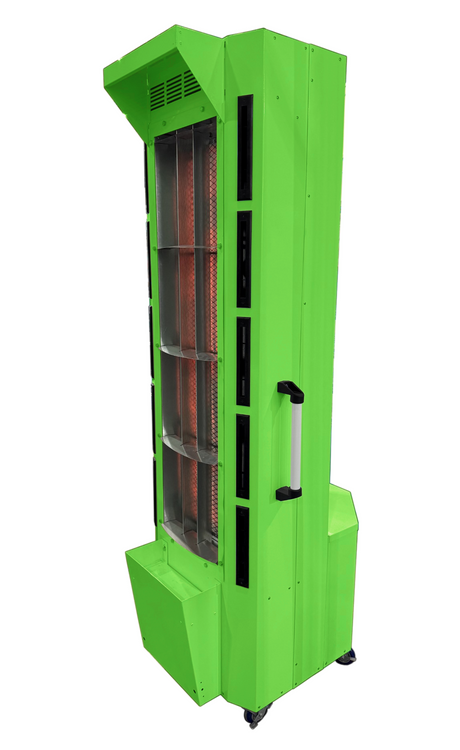

150 PSI Vessel It’s simple, more psi = more productivity. To give you the best possible productivity, E-Series pressure vessels are ASME certified and Canadian Registered for all provinces for everyday use at 150 PSI (10.3 BAR)

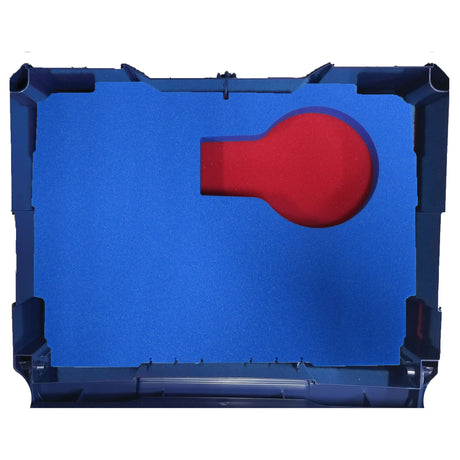

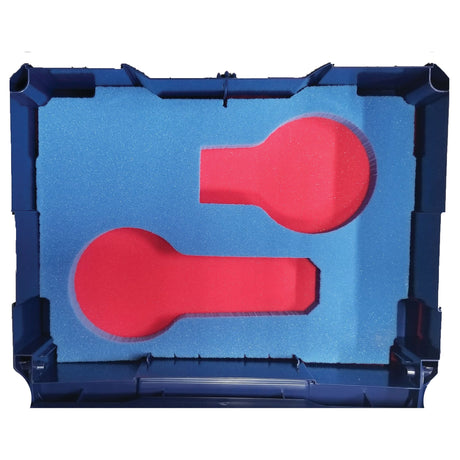

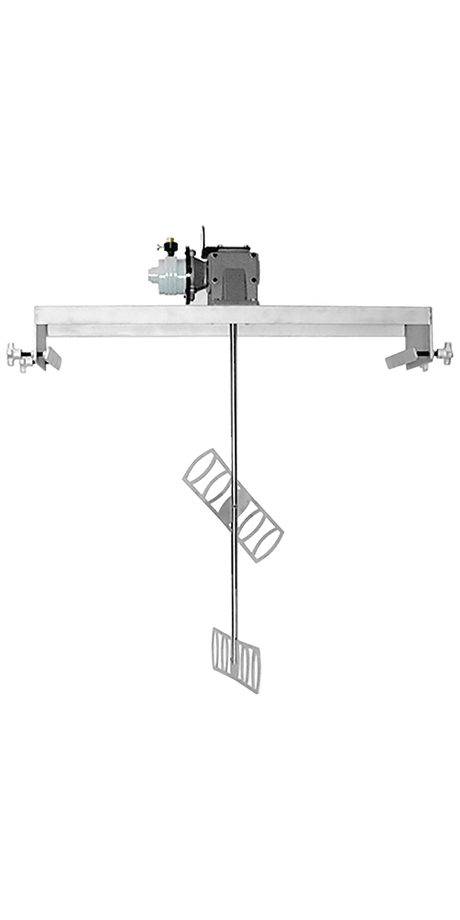

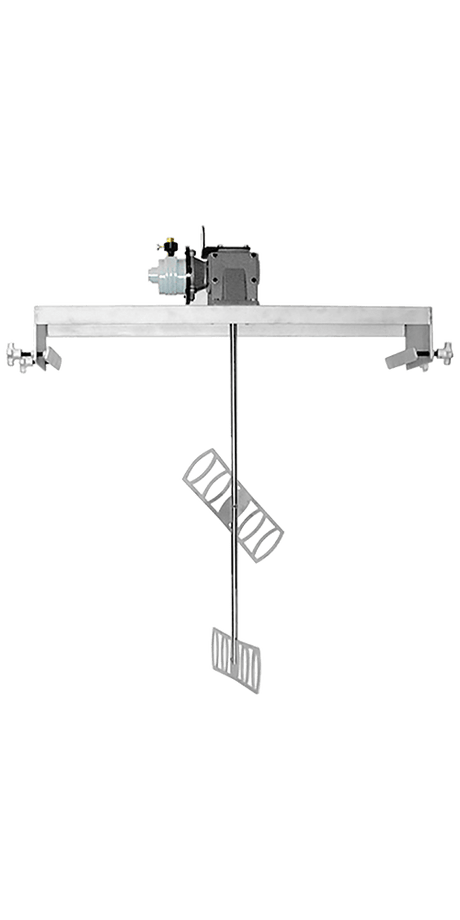

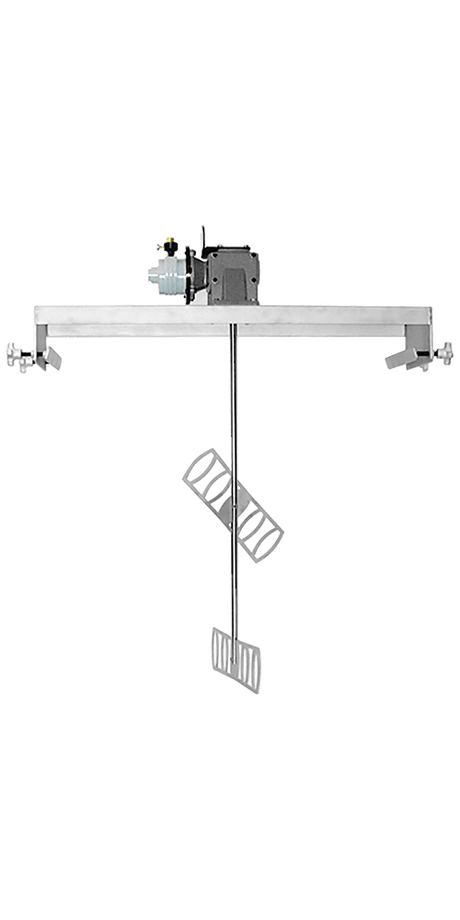

2 Capacities E-Series portable blasters are available in 3.5 cu ft and 6.5 cu ft abrasive capacities.

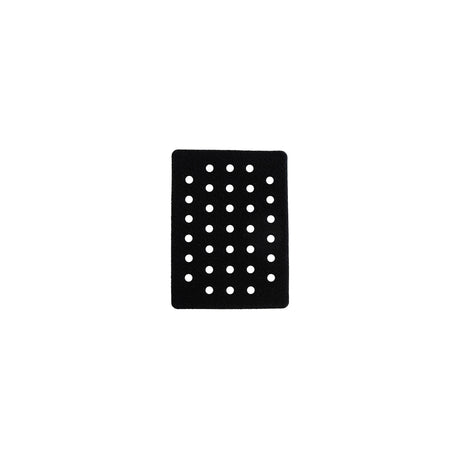

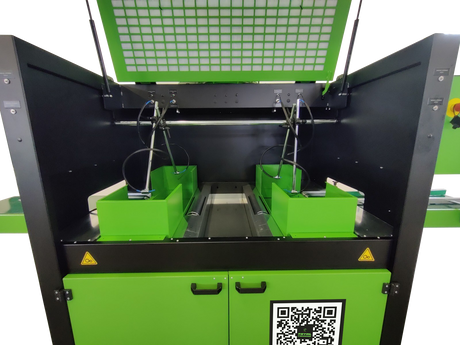

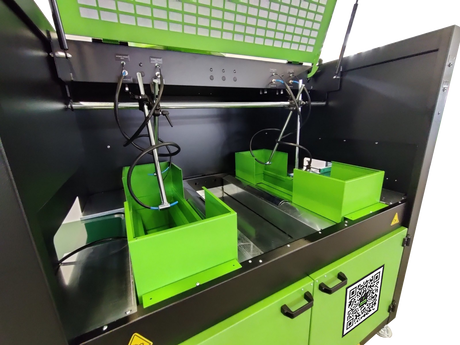

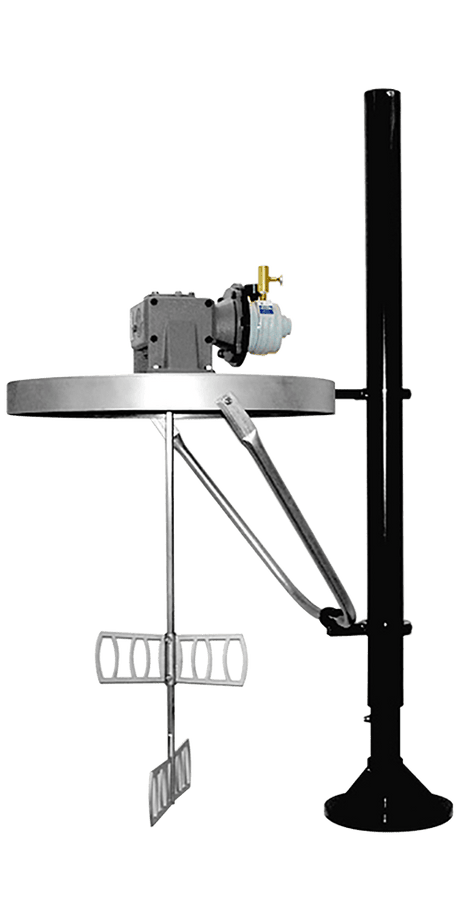

Bag-Breaker/Screen or Optional Umbrella All E-Series portable blasters come standard with a built-in bag-breaker and screen. EPH & EPR Blast Room Series Blasters come standard with an overhead umbrella to keep weight off of the pop-up.

Exhaust Valves EPR (Pressure Release) models include our X-Treme Duty #2 or #8 exhaust valves which feature an improved valve ball for extended life and superior durability.

Fast-Fill™ Pop-Up Every E-Series blaster comes standard with a large 6” pop-up for faster filling.

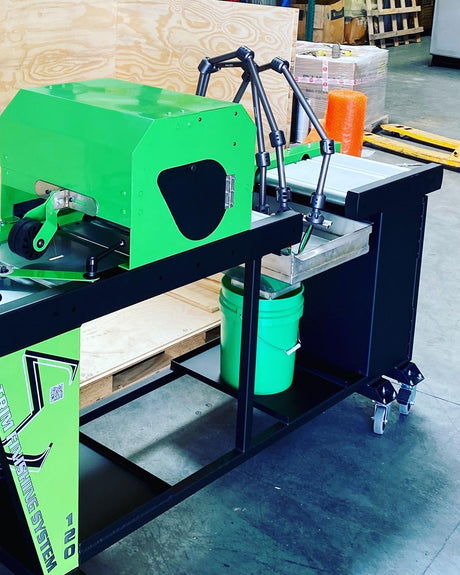

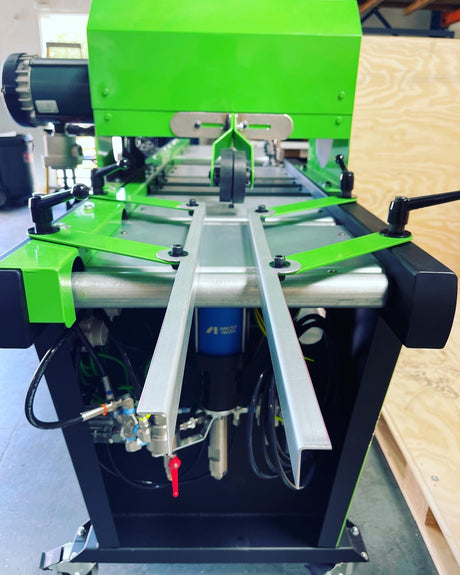

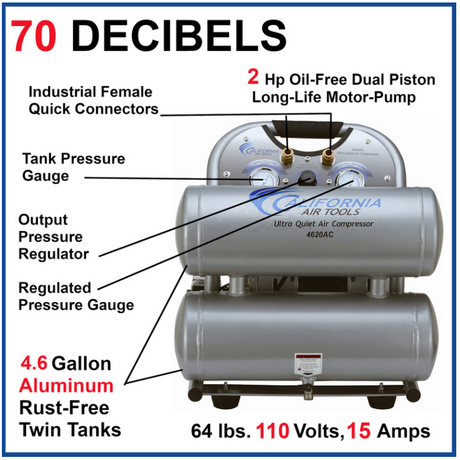

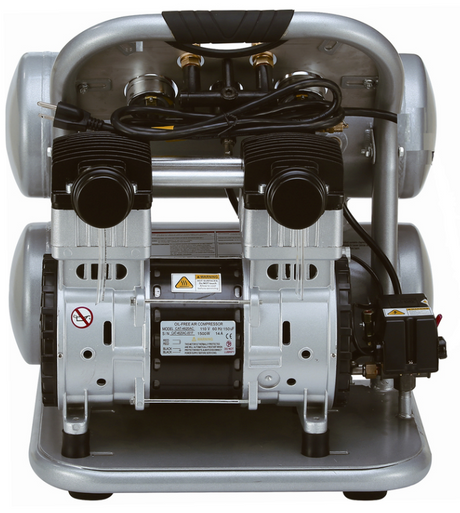

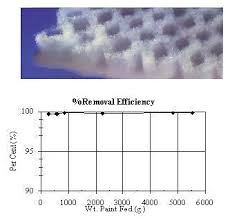

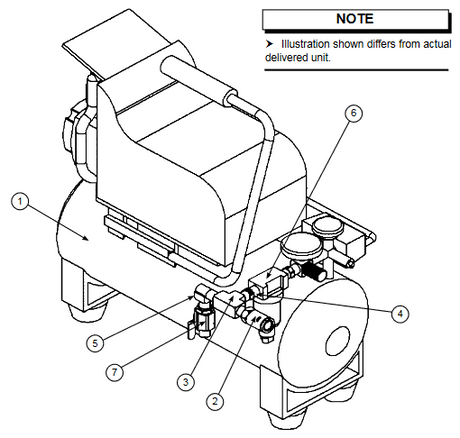

Moisture Separator As a last defense against clog causing moisture, all E-Series blasters come standard with a moisture separator or 50 micron air filter.

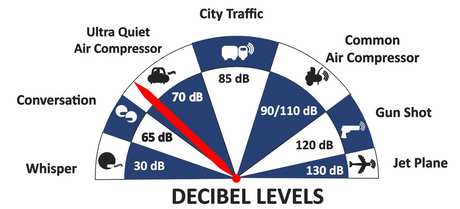

Pneumatic or Electric Controls Choose between pneumatic or 12VDC electric controls.

Electric controls are recommended for blast hose lengths longer than 100’, feature faster starts/stops, and are less prone to freezing in cold climates.

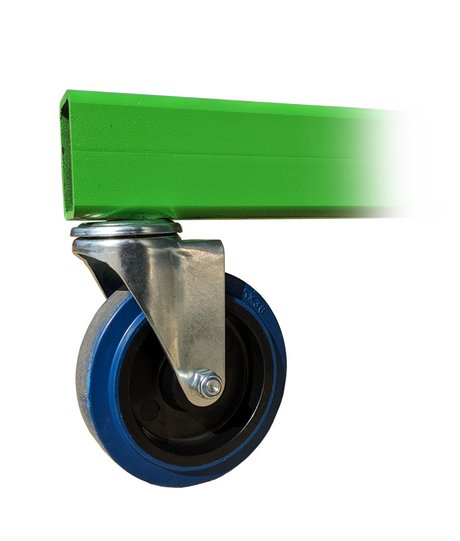

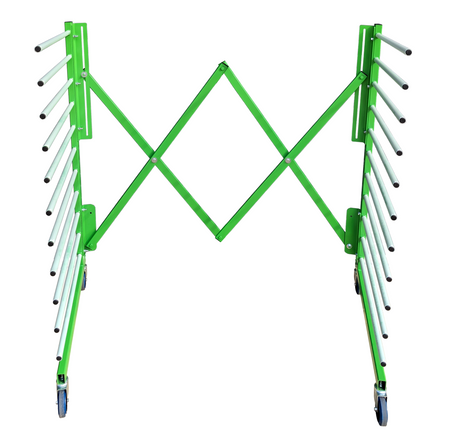

Portable or Blast Room E-Series Blasters are available in portable models with wheels or stationary models for blast room applications.

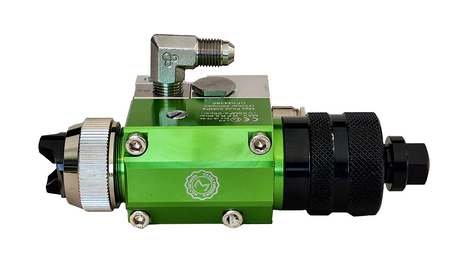

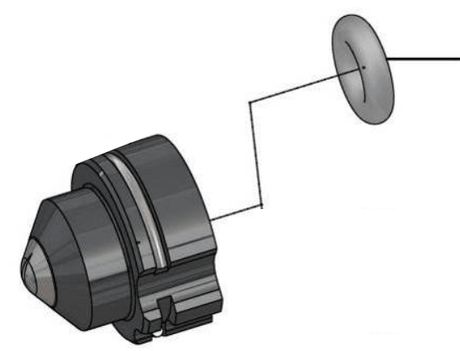

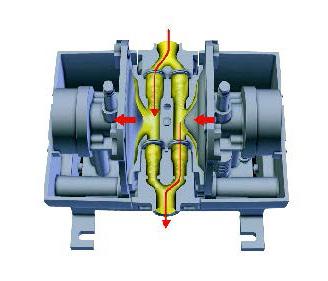

X-Treme Duty Metering Valves Both the Pirate Brand® Manual and Automatic Pinch Metering Valves feature the X-Treme Duty metering tube for extra long service life and durability. The tube also features carbon black to aid in dissipating static buildup.

Pressure Release vs. Pressure Hold

Release- Automatically blows down vessel when control handle is released.

• Commonly used in blast room applications where an overhead hopper will automatically fill the blaster when it blows down.

• Good choice for first time blasters & rental houses.

Hold- Stays pressurized until manually blown down.

• Reduces abrasive consumption • Reduces moisture problems

• Smoother starts & stops • Stands up to short blast cycles

• Commonly used in one-shot media blasting, corn cob blasting, precision blasting applications & when short blasting cycles.