- Up to 20% off

Total Finishing Supplies Spray Booths

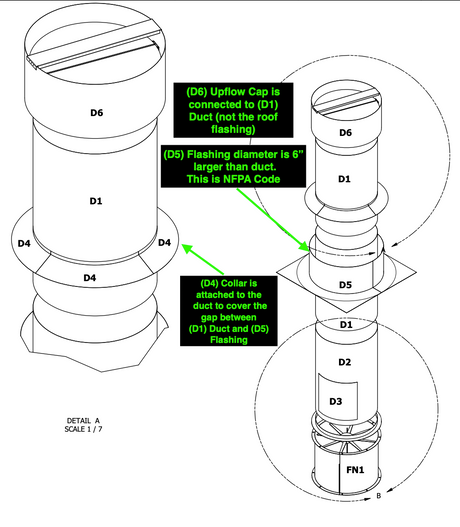

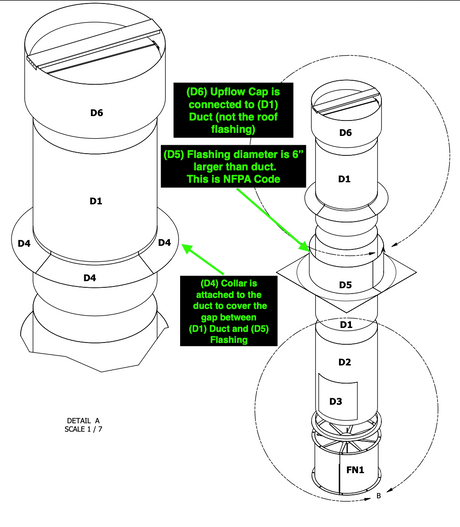

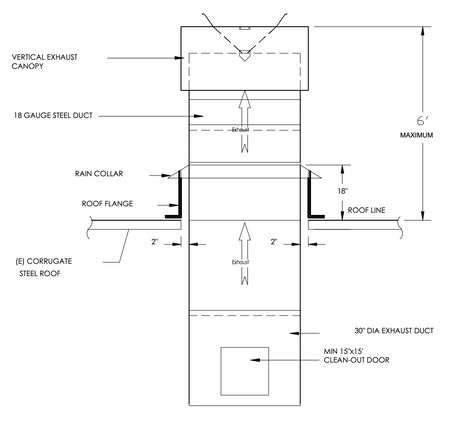

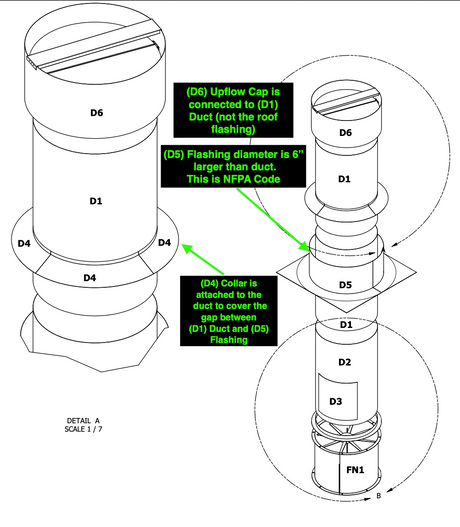

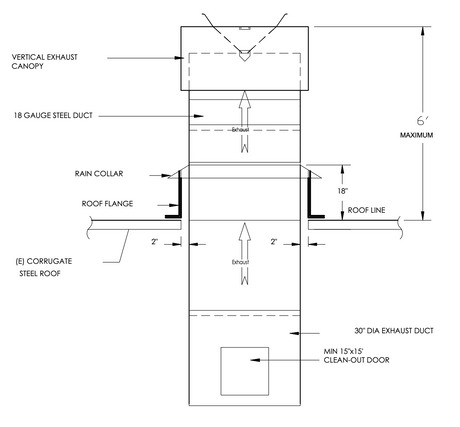

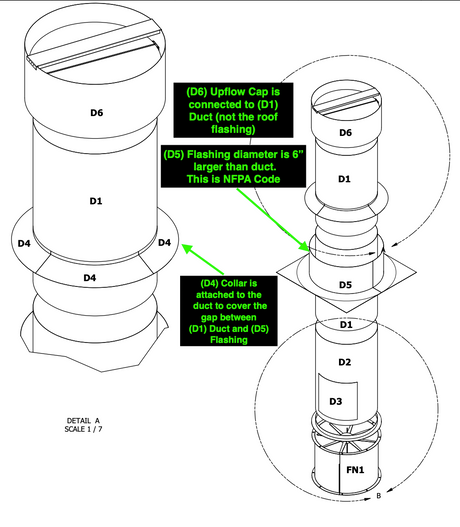

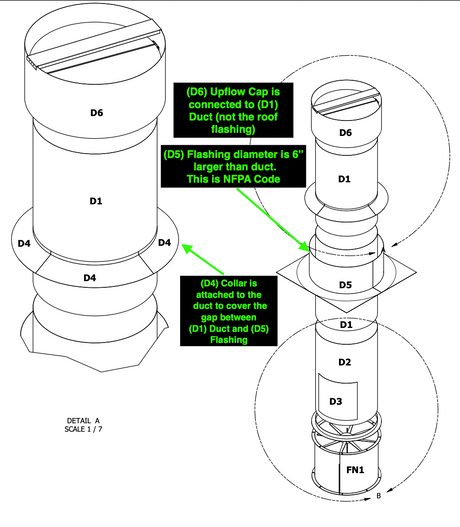

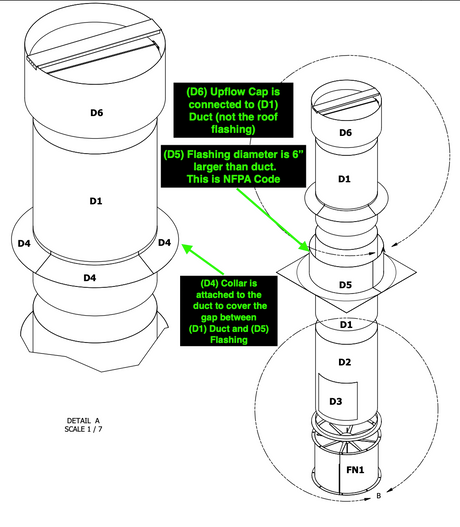

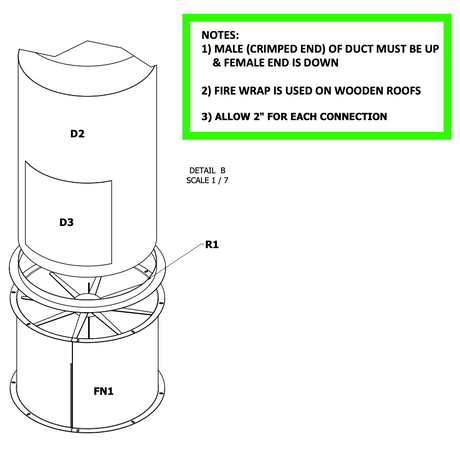

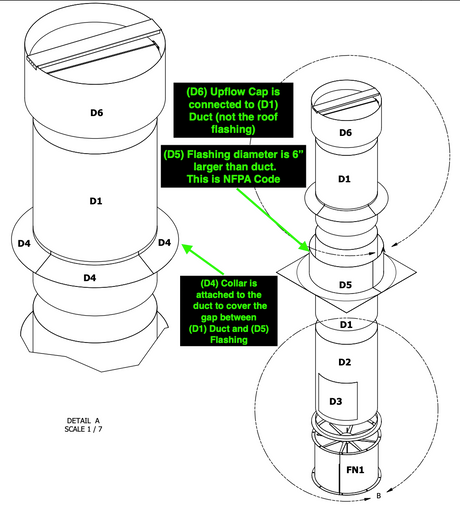

Upflow Cap with Damper - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 21% off

Total Finishing Supplies Spray Booths

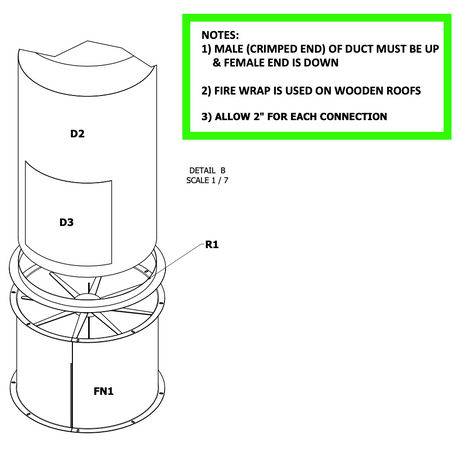

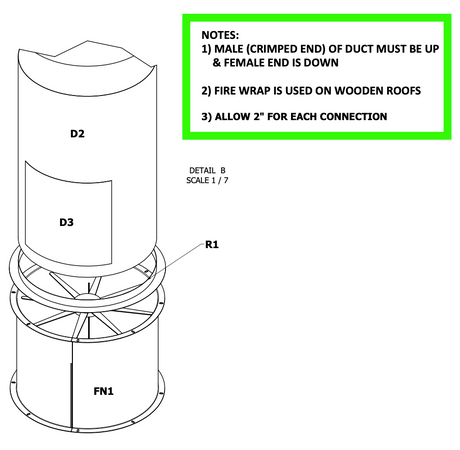

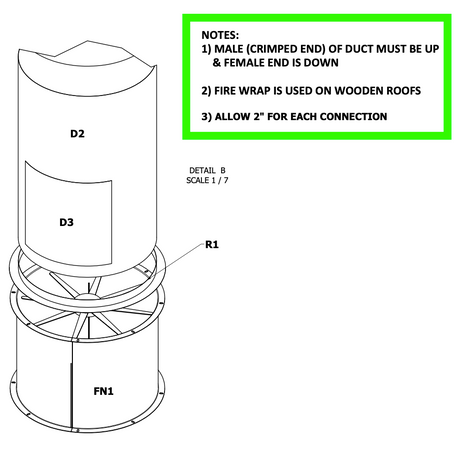

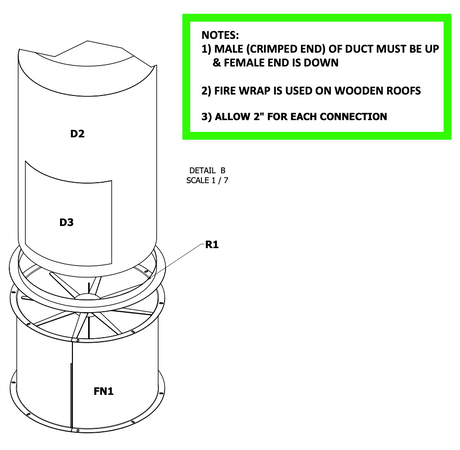

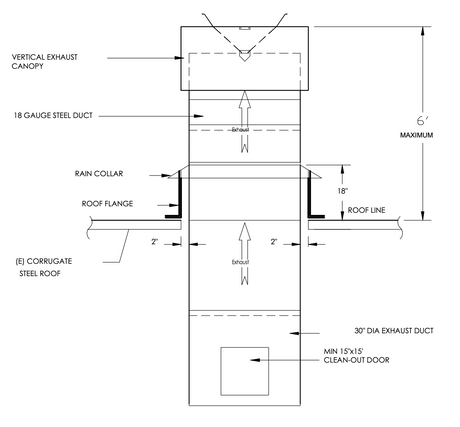

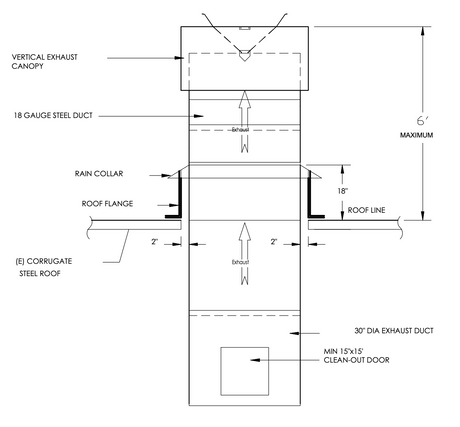

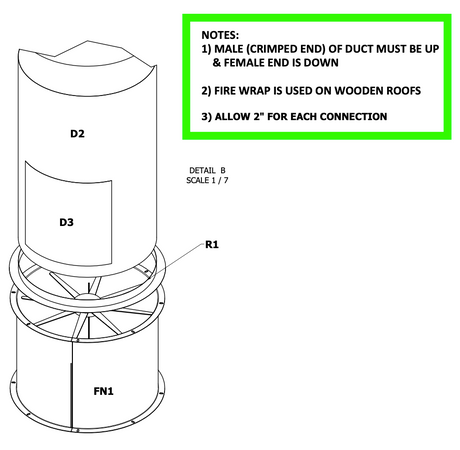

Standard Exhaust Stack - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 21% off

Total Finishing Supplies Spray Booths

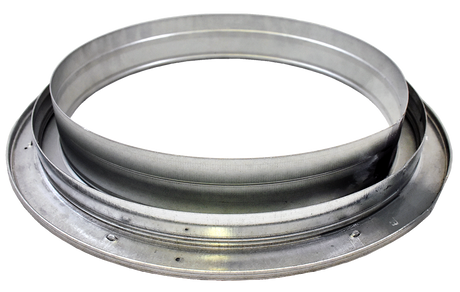

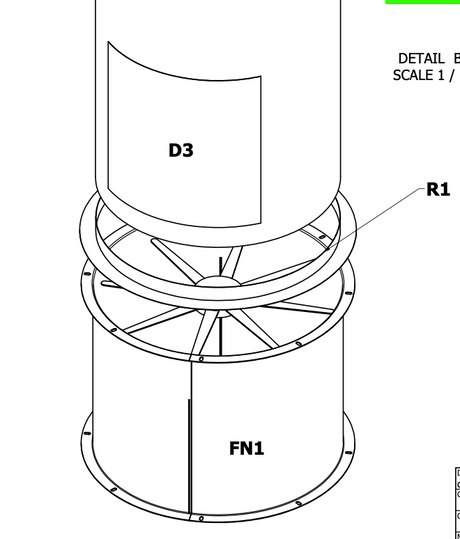

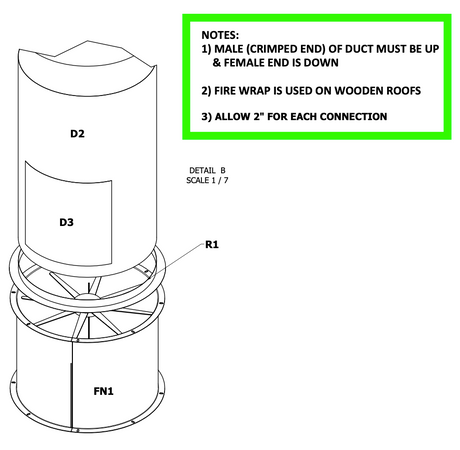

Stack/Connector Ring - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 20% off

Total Finishing Supplies Spray Booths

Standard 90 Degree Elbow - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 21% off

Total Finishing Supplies Spray Booths

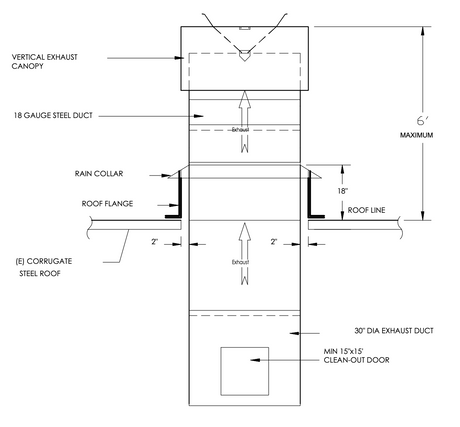

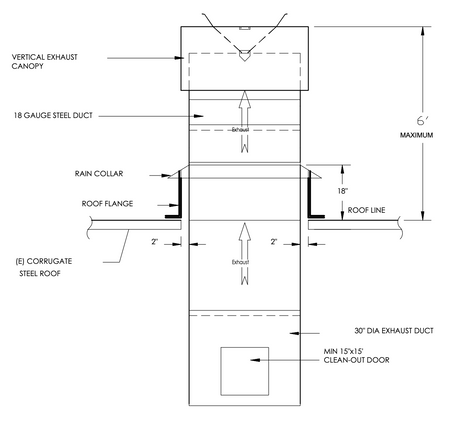

Exhaust Stack with Cleanout Door - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable Total Finishing Supplies Spray Booths

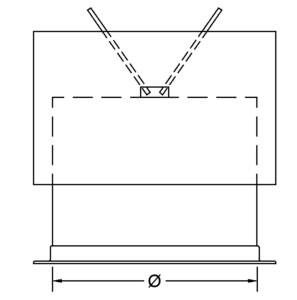

Duct Quarter Section Skirt (Storm/Rain Collar) - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable- Up to 20% off

Total Finishing Supplies Spray Booths

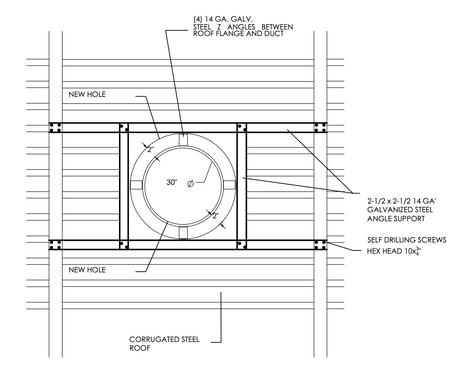

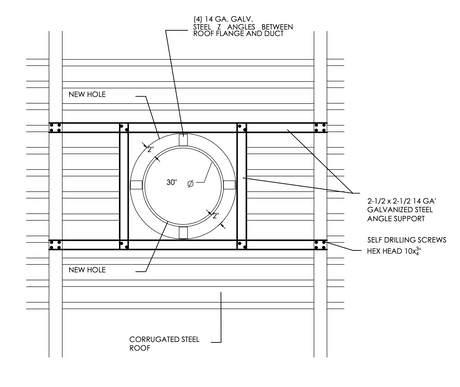

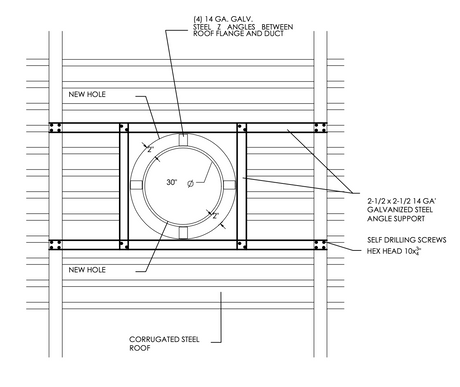

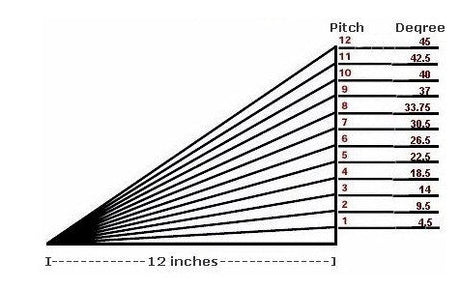

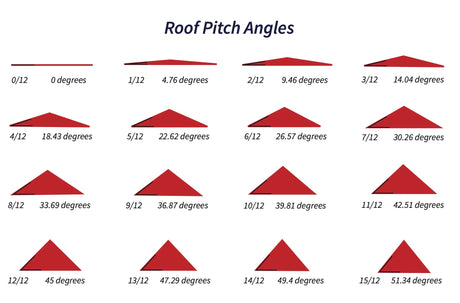

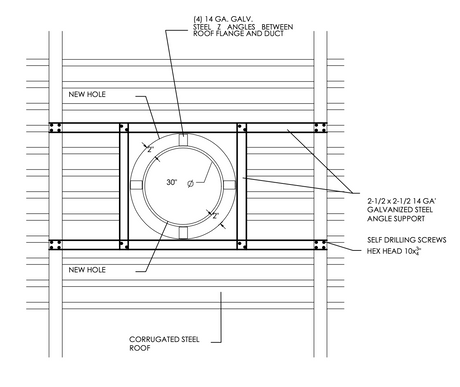

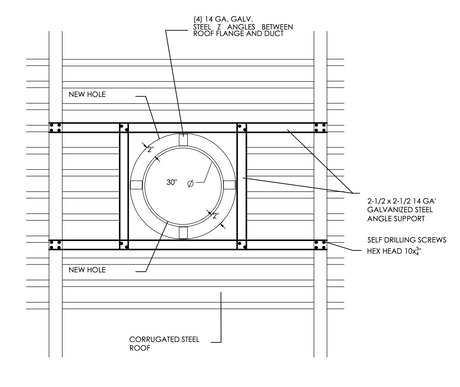

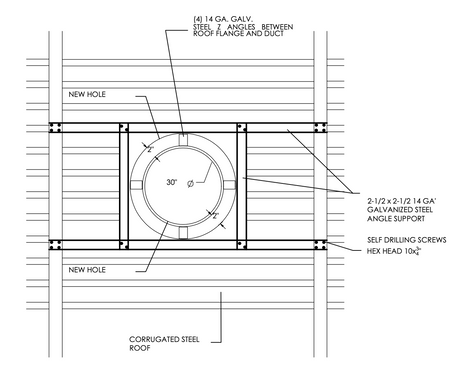

Standard Roof Flashing for Pitched Roof - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 21% off

Total Finishing Supplies Spray Booths

Standard Roof Flashing for Flat Roof - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 21% off

Total Finishing Supplies Spray Booths

Standard 45 Degree Elbow - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable - Up to 90% off

Total Finishing Supplies Spray Booths

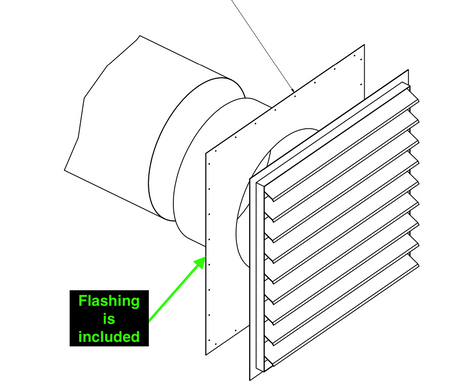

Wall Shutter - Paint Spray Booth

Sale price From Regular priceUnit price /Unavailable Total Finishing Supplies Spray Booth Filters

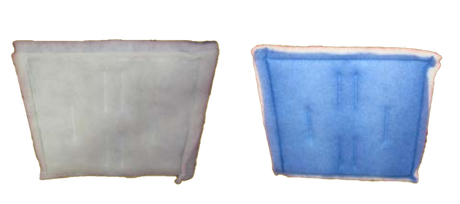

Mono Fiberglass Paint Arrestor Pads (Exhaust Filter)

Sale price From Regular priceUnit price /Unavailable- Up to 20% off

Total Finishing Supplies Spray Booths

Sale price From Regular priceUnit price /Unavailable Total Finishing Supplies Spray Booth Filters

Super Grade Fiberglass Media Roll

Regular price FromUnit price /UnavailableTotal Finishing Supplies Spray Booth Filters

Regular price FromUnit price /UnavailableTotal Finishing Supplies Spray Booth Filters

60"X90' Poly Exhaust Blue Roll PEB609

Regular priceUnit price /UnavailableTotal Finishing Supplies

Air Filtration Co New CT Series 20"x20"x1" Filter Panel

Regular priceUnit price /Unavailable